Korchmar :: What We’ve Learned in 100 Years of Making Bags

Korchmar. It’s a name that’s been around the carry block. Rare it is, in this day and age, for a fourth generation enterprise to be alive and thriving, especially one that still keeps it in the family. As you’d expect when you’ve scratched up 100 years in the game, these guys know a thing or two about making bags – looking ahead to their centenary anniversary, we chatted to current President, Michael Korchmar, and picked his brain on some of the juiciest carry learnings that have propelled his family brand’s century-long success.

Keep it in the family

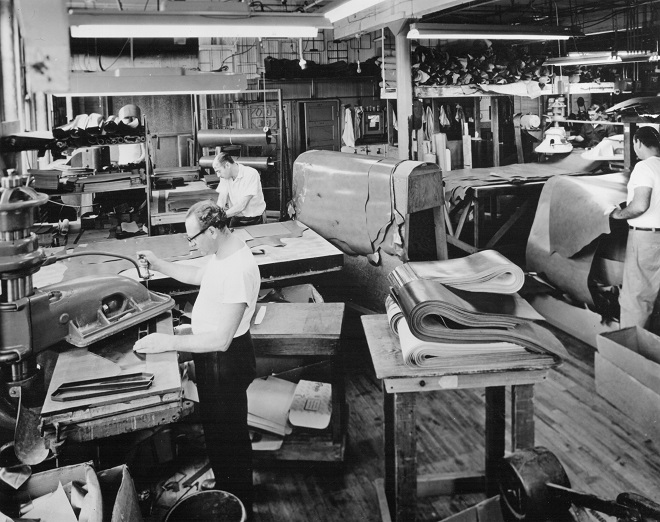

Korchmar is a family-owned, family-run deal. Michael’s grandfather, Max kicked the biz off in 1917 after immigrating to America from the Ukraine. Landing in Baltimore, he started making leather visors for automobile headlamps. Carry gear followed: for the military, then the public. Michael’s dad and uncle took over after the war, both vets – his dad, a brilliant engineer, who designed machinery to automate the production process and enhance bag quality. Michael took the reins in ’77, and his son and daughter are now waiting in the wings.

“The advantage is having someone 150% ‘bought in’ to the business for life,” says Michael. “(But) it depends on the family members, (and if they) share the creative passion to not just mass produce a ‘product’ but to create beautiful articles […] Most everything I know came from my father in this business; knowing that someday it will be yours and that you are the master of your own destiny does foster hard work and devotion […] The pressure of maintaining a legacy is always there.”

Ain’t always shirts to shirts

“There’s an old saying in the States,” says Michael: “Shirt sleeves to shirt sleeves in three generations.” (It’s actually an American translation of a Lancashire proverb: ‘Nobbut three generations atween a clog and clog’; or the Italian ‘dalle stalle alle stelle alle stalle’ – from stalls to stars to stalls).

In short, when it comes to family business, someone usually starts it, the next generation reaps it, and the third tends to run it into the dirt. It takes nous to baulk the inertia of nepotism: “Fortunately, I beat those odds,” says Michael. “But there’s been some hard times.”

Stay flexible, but stay true (and bring it home where you can)

As well as the plant in the Dominican Republic (DR), Korchmar has a thriving HQ in Naples, Florida. “One of the missions (in recent years) has been to try and bring as much work back to the US as possible,” says Michael. Staying competitive while keeping things local can be a tough deal to juggle, though much of Korchmar’s longevity comes from striking that balance.

“As well as the plant in the Dominican Republic (DR), Korchmar has a thriving HQ in Naples, Florida. “One of the missions (in recent years) has been to try and bring as much work back to the US as possible,” says Michael.”

Michael took the reins at a time when foreign competition, and cheap labour, began to pervade and transform the market.

“Everyone else in that time either went to China/Asia, or went broke, he says. “We started a plant in Mainland China between 1982 and ‘85. It just felt dirty – ‘this is not the right thing to do’.”

In 1985, (then US President) Reagan started a ‘Caribbean Basin Initiative’: “It sounded like a really cool idea to start a plant closer to home. We built a plant in the Dominican Republic (DR) in 1986, and over the course of the years it allowed us to really survive.”

By the late ‘90s there was nobody left manufacturing in a production environment on that side of the world. Shortly after 2001, Korchmar started seeing renewed interest in sourcing goods on this side of the world. By staying flexible in a changing industry – maintaining operations locally between the US and DR – they were well positioned to reap the benefits when the market shifted back to a more artisan-based, localised approach.

Can’t avoid hard work (nor would you want to)

“I did everything I could to avoid it,” says Michael about the family game. “Getting back to the old third generation thing, I wanted to party, wanted to have fun, and this was hard work…I mean, this factory work is not for sissies. It’s dirty, it’s hot, and I was a little more interested in trying to have fun. My father insisted I work or I didn’t eat basically. So I had to work. I got out of college, tried to go to Law school, did everything I could – I guess I did always know, I just wanted to put up a fight about it. I’m sure glad I’m not a lawyer.”

““I did everything I could to avoid it,” says Michael about the family game. “Getting back to the old third generation thing, I wanted to party, wanted to have fun, and this was hard work…I mean, this factory work is not for sissies…””

Family doesn’t end with the bloodline

So many of Korchmar’s artisans and patternmakers have been with the company for a generation – a cadre of 15-18 people chalk up between 27 and 35 years each. Even the Vice President started in ’77, the same year Michael took the helm. Retention through mutual loyalty is paramount: a feeling of family that doesn’t end with the bloodline.

“One of the sad things about today’s economy is that is so very rare. When I started in business it was the norm. With that said, I don’t know the ‘key’ to retention except that it seems to help when the owners actually work – I mean every day, on the floor, with the people. It’s hard to imagine why the team would care so much unless they see that the owners sincerely care […] I hope that’s why they’re here – either that or I’m paying them too much,” he jokes.

“I don’t know the ‘key’ to retention except that it seems to help when the owners actually work – I mean every day, on the floor, with the people.”

There’s more to business than money

“There’s nothing to be embarrassed about in business about trying to make money – if you don’t, you don’t survive and you can’t do any good,” says Michael. “At the same time, it can’t be your only reason for being. As businesses grow and become part of operations that can only respond to shareholders, they lose some of that warmth and caring. I couldn’t go to work every day if it didn’t mean something: if I wasn’t doing something positive for the world by providing employment and opportunity.”

Don’t be a copycat

You can’t deny a trend in the market, but to be successful as a brand you need to improve on it. “You never try and copy,” adds Michael. “You always try and see a trend – and then reinvent to do something better. You can’t just duplicate. That’s what we tried to do.”

“You can’t deny a trend in the market, but to be successful as a brand you need to improve on it.”

Know your product

“Our skills are unusual – almost 100 years working with leather. We really know leather. We were able to make strides and improvements in product based on material quality. Where the marketplace was using very cheap leathers to try and hit price points, we were able to differentiate by being very pure to Max’s philosophy of only using the finest raw materials.”

From the grain selection to the actual tanning process, leather is a complex art. But in short, the grain is what provides the flexibility to the leather and thus, to a great extent, its longevity and beauty. Korchmar never uses anything but Full Grain or Top Grain leather on its products – i.e. the outermost layer of the animals’ skin (or as close to as possible).

“We were able to make strides and improvements in product based on material quality. Where the marketplace was using very cheap leathers to try and hit price points, we were able to differentiate by being very pure to Max’s philosophy of only using the finest raw materials.”

“The moral of the story is never buy anything labeled ‘Genuine Leather’,” says Michael. “If the manufacturer knows anything about leather and is truly using the ‘real deal’ they will be the first to mark the product “Full or Top Grain.”

Work with others

Korchmar are their own line, but they’ve been helping other brands realise their design mission for decades. “We make for major brands – Hartmann, Tumi, T Anthony, Coach. You learn how to improve by making for others.” Leveraging off the knowledge of other established brands has translated a lot of that practicality and good design sense into the Korchmar line.

“You learn how to improve by making for others.”

D to C ain’t the be-all

It’s rare today that any brand makes product from scratch. More often than not, if you buy a product you’re not buying something that the brand made, but something they sourced. “I know there’s a big move around this whole direct to customer (D to C) concept. Well that’s cool…you’re not selling through a retailer…but you’re not making it either, so you still got a middle man in there. Korchmar is as much D to C as any company, simply because we own the factory, and the people who run the company are on that factory floor, working with the people every day, trying to figure out better ways to make product.”

Bottom Line: Values

Max’s vision and ethic back in the day was pretty simple: Make quality products using the finest materials, produced by positively motivated people – to make people want to do beautiful work. It’s a simple formula, though hard to achieve – “especially when people are barking down your neck for profit,” adds Michael.

“Korchmar is as much D to C as any company, simply because we own the factory, and the people who run the company are on that factory floor, working with the people every day, trying to figure out better ways to make product.”

In the long run, base level values around quality are the key to longevity. “Bags that compromise quality don’t last. Simple as that. When you try to compete strictly on price, you fail in the long term. You’re headed down a very slippery slope. Those were the values instilled in me from the very beginning. It’s quality, and it’s quality through engineering: you have to design methods of making the product that make it easy for people to do well making it. There’s a hard way to do everything, and there’s an easy way. The easy way takes a lot more work upfront…but if you do it, you’ve got a good shot at having a team that can be successful and enjoy their work. The key is having your people enjoy what they are doing.”

“Bags that compromise quality don’t last. Simple as that. When you try to compete strictly on price, you fail in the long term.”

–

Giveaway

Keen to experience Korchmar quality for yourself? Enter our giveaway and you could be adding serious luxe to your business carry. Up for grabs is one Korchmar Monroe Leather Attaché Case. Crafted by hand, this case exudes class with its premium materials and meticulous construction. Full grain American leather is complemented by solid brass hardware, with a combination lock keeping the contents safe and secure.

The interior of the case features a choice of pockets for organization, and will fit up to a 17″ laptop. If you want to carry like a boss, this piece will give your work EDC an instant promotion.

How To Enter

.

Follow both @Carryology x @korchmarbags on Instagram and tag two friends on this @korchmarbags photo.

Winner announced and contact via DM on Instagram, Dec 13th.

.

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews