QWSTION: Is Bananatex the Next Miracle Backpack Fabric?

They’re breaking out the good champagne at QWSTION HQ, and the Swiss-based brand have a lot to celebrate. Firstly, this October marks the brand’s 10th anniversary. 2018 also marks an environmental milestone with the brand switching all external fabrics to certified organic, a huge effort in terms of sourcing and certification. But perhaps the most exciting announcement was yesterday’s release of a new shell fabric dubbed Bananatex®, a unique banana-based material that promises to be the most sustainable bag fabric yet. According to Christian Kaegi, co-founder and Creative Director, “We are super excited about the launch of our Bananatex® collection, as it’s the culmination of several years of research and development. It’s so difficult nowadays to deliver true innovation – with this we knew we were on to something.” Amongst all the festivities Christian took time to sit down for a chat, share the details of their new fabric, and ponder if bananas can save the world.

One of QWSTION’s defining traits has been their commitment to organic materials, a decision the brand made at the very beginning. The group were searching for a path towards a truly sustainable product, one that factored in the entire product life cycle. Christian and the team took a pragmatic view of the situation, “So long as there is no effective end-of-life strategy for synthetic materials, natural fibers are going to be more environmentally friendly”. Theoretically synthetics can exist in a closed loop with old fabric being recycled into new, but for now natural fabrics have a more established loop. Plants provide a renewable source of material that is able to return to the earth to complete the cycle. The production of natural fibers also produces less emissions and plants even convert carbon dioxide back into oxygen. Whilst the environmental justification was there, the choice to go natural organic was a brave one considering that good-quality nylon is both stronger and cheaper than cotton. Here Christian and the team again questioned the norm, “Sure tech fabrics will always be stronger than an organic material, and can maybe last for 100 years, but is that really necessary?”

A major environmental concern for the majority of natural fibers available is their reliance on large quantities of fertilisers and pesticides to produce high yields. These practices have been linked to a range of environmental issues including water pollution and health problems for farmers. As a countermeasure QWSTION set about developing a shell fabric made from certified organic cotton. However, cotton is generally grown to produce short fibers for soft t-shirts, which isn’t ideal for durable structured pack cloth. Whilst working with a fabric mill to solve that puzzle, the team were introduced to the Abacá plant, a member of the banana family. Christian says right away the plant had two promising characteristics.

Firstly the cultivation of Abacá is almost wild. Commercial growing in the Philippines looks more like a jungle than a farm. As the plant thrives within a natural ecosystem there is no use of pesticides or irrigation, and according to Christian, Abacá has even contributed to reforestation efforts in the Philippines. The farming also has a positive social impact in line with QWSTION’s ethical production values. Secondly, and as important, the fiber from the plant was long and strong. This gave it the potential to make a great pack cloth.

Abacá is by no means a new fiber; it’s been grown commercially since at least the 1500s. Before the rise of synthetic fibers it was commonly used around the world in the form of ropes and basic cloth; these days it’s used mainly to produce tea bag paper. The innovation that took QWSTION three years was in evolving the end product from the primitive to the technical.

“The cultivation of Abacá is almost wild. Commercial growing in the Philippines looks more like a jungle than a farm. As the plant thrives within a natural ecosystem there is no use of pesticides or irrigation.”

The first steps in production are the same for both old and new processes. On site at the plantation, stalks are cut from the plant and stripped by hand into long spaghetti-like strands. These are air dried at the plantation for two days before being graded, bundled and shipped to a processing plant.

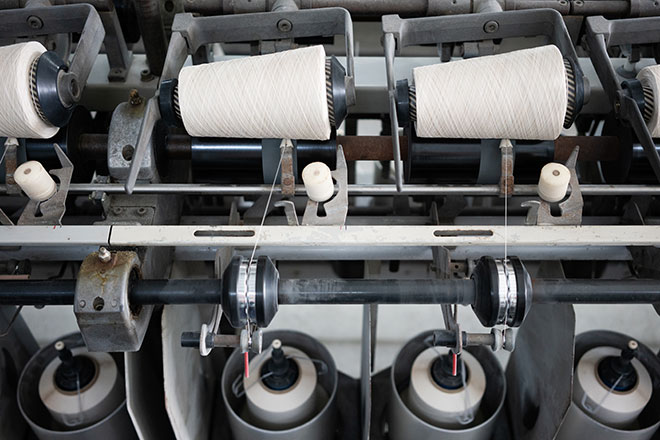

It’s at this point where QWSTION developed a unique and slightly convoluted process. The fibers are pressed into large pulp sheets in the Philippines before being shipped to Taiwan where they are then soaked in water to create long rolls of thin paper. The paper is then cut into thin strips and spun into Bananatex® yarn. Once in yarn form Bananatex® has endless possibilities. Its first incarnation is a sturdy shell fabric treated with a natural beeswax for waterproofing. The result is a really likeable fabric with a canvas-like quality to it. The hand feel is unique, smooth like a synthetic and slightly crunchy. Christian says early lab testing is looking good. Its strength and abrasion resistance are still not at the level of Cordura, but more than enough for your daily carry. Or as he puts it, “Our pack can carry 100kg of concrete, a Cordura pack could carry 300kg. Nobody is ever going to carry 300kg of concrete.”

“The fibers are pressed into large pulp sheets in the Philippines before being shipped to Taiwan where they are then soaked in water to create long rolls of thin paper. The paper is then cut into thin strips and spun into Bananatex® yarn.”

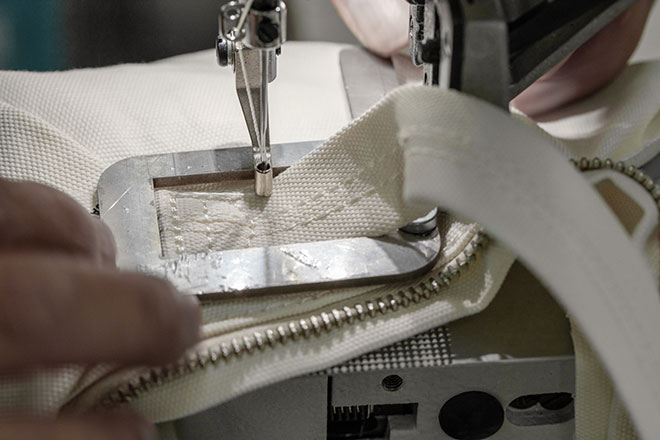

Bananatex® is being launched in two new styles each designed with the same dedication to sustainability. There’s an everyday roll-top pack and a hip pouch that doubles as a small utility pouch. To complement Bananatex®, the rest of the fabric palette is meticulously minimal. The backpack is made from only five materials. Vegetable-tanned leather has been used on touch points, and aluminum for the custom-designed hooks. There’s no lining or webbing to be seen, and instead of foam padding for your laptop there is very clever use of thick wool felt. This approach minimises the environmental impact of the bag at both ends of its life cycle as there are fewer production processes, and the bag can be more easily recycled. According to Christian, once the metal and zips have been removed the bag is completely compostable. Put simply – less complexity is less impact.

Like a chef cooking with top-quality ingredients, the designs are simple and allow the fabrics to be the hero. The patterns have zero cutting waste which Christian says was a challenge to achieve whilst aiming for maximum functionality. A good example of the thinking is the versatility of the backpack. Its simple detachable leather handle allows you to roll and carry the pack in a number of ways, giving you a range of personalities to choose from. And the aluminum hooks are used again on the pouch to convert it into hip pack form. By creating flexible products that can be used in a number of ways Christian hopes to reduce the need for people to buy multiple products.

As dyeing is one of the chief causes of environmental impact in the production phase, both styles are being released in two colors chosen to minimise harm. The classic all-black has been yarn-dyed using the most sustainable practices available. But to go one step further and eliminate the problem altogether there is an undyed natural white.

As someone who’s seen the realities of fabric manufacturing I have a huge appreciation for the effort that has gone into creating Bananatex®. The textiles industry has one of the longest and most complex supply chains and creating change takes commitment at all levels. Once the material is produced there are further challenges in quantifying the environmental impact, which often makes it hard to promote the benefits achieved. QWSTION seem to be asking the right questions and are showing a commitment to sustainability like few others. They are even offering Bananatex® as an open source material, meaning other brands can take advantage of their good work in order to maximise the positive environmental benefits.

For Christian and the team the greatest opportunity for Bananatex® is also its greatest challenge. “The biggest impact lies in the communication and how this can help to change consumer awareness and behavior”. For Bananatex® to make a real difference it’s going to require a shift in customer thinking similar to the one that occurred in the car market in which environmental impact became a major purchasing consideration. The majority of the bag market is currently filled with cheaper synthetic bags and big brands in an arms race for ultimate functionality. Spending time with the QWSTION bags I notice that the simplicity of the design does sacrifice some ease-of-use. There is a level of forethought required to pack and use the bags which I’m comfortable with only because I understand the thought behind the design. Ultimately, given QWSTION’s clear dedication to sustainability and commitment to balanced design over pure functionality, I can’t help but think that the brand’s name is directed at us, the customer, as a challenge to ‘question’ our own choices and to look more deeply into the things we buy.

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews