Carry Collaborations

Growing up in the green suburban streets of Reston, Virginia, Mark Falvai, co-founder of Mission Workshop, found inspiration in an unlikely pair: Evel Knievel, the motorcycle daredevil, and the intrepid astronauts kitted out in NASA spacesuits, embarking on their missions beyond Earth’s grasp.

As a youth, Falvai recalls his escapades with his father, scouring the aisles of the local department store for rocket kits and building them in his backyard. They were the kind they don’t make anymore: tall cardboard cylinders with gunpowder inside and batteries, engines, and fuses. Each launch was a mesmerizing spectacle as they pierced the heavens, leaving only wisps of smoke behind.

In retrospect, he muses during our virtual call, he’s always been a self-professed “rocket nerd.”

So in 2016, when his inbox pinged with a new message from an engineer named Mike Miller from the National Aeronautics and Space Administration (NASA), he leaned unusually far back in his seat.

NASA was preparing for Mars Landing and they needed special packs to carry their equipment for their mission. They’d tried off-the-shelf solutions but nothing came close to their exacting standards. And so their research had brought them to Mark and Mission Workshop – and they believed Mark was the right person to help.

The project would be challenging. It was called BASALT. And scientists and engineers were teamed up to simulate Mars exploration in volcanic terrains. They’d set up a communication system similar to what they’d need for Mars missions – this involved the astronauts carrying heavy GPS devices weighing 50 pounds – allowing crew members in the field to talk to those in a control center on Earth.

The simulations would occur in three different volcanic terrains: Idaho, Hawaii, and Iceland. These terrains were intentionally rugged and mimicked Mars’s surface. It would be rocky, uneven ground where you might have to drop to your knees or swing a hammer just to get around, while lugging seriously heavy loads. The packs they’d tested before were heavy and had been torn to threads by jagged rock or melted by the acid rain found in the volcanic areas. There were also other challenges like access to their gear such as spare batteries and tablets. Protecting their comms devices from the outer space elements, high wind, rain, and extreme cold and heat. The differing heights and body shapes of their astronauts. And how to tell each specialist astronaut apart when on the Mars surface, so their comms lead could help manage the data collection in real time.

Mark tells me he underestimated the challenge and the intensity of working with NASA at the time, but he couldn’t say no; it was too damn interesting to pass up.

Before he knew it, he was traveling to the Ames Research Center, located in the heart of California’s Silicon Valley. After passing through the many-tiered levels of security, he was chaperoned by a team of scientists and engineers and led to a meeting room full of equipment and wires and blueprints splayed across desks. He was shown the tools they’d use and the communications apparatus. He’d brought a first prototype based on their initial calls and whiteboard sketches, and they’d test it first in their Roverscape, a rocky outdoor area the size of two football fields, sitting in a trailer behind a big glass window to observe the test and gather their first design notes on changes and improvements.

“Development came right down to the wire”, Mark says. Each pack took 10 days to make and had to be handmade, to make sure that every stitch was perfect, and so he sewed into the night, finally shipping the eight packs needed to Idaho as NASA had just embarked on their plane flight.

The backpack would be called the BASALT EVIB (EV = extravehicular and IB = Informatics Backpack) and Mission Workshop rolled along to the testing terrain, to chronicle and document the tests.

Mark had finely tuned the EVIB and it performed extremely well. It was a triumph of problem-and-solution design, and here’s how it shaped up…

Gear and Load

The softshell backpacks of the EVIB were tailored to accommodate the communications apparatus, including the GPS antennae, and were bolstered by an internal frame, added straps, reinforced double bartacking, COBRA buckles, and load lifters. Special attention was given to securely mounting the shoulder camera, antennae, and managing cable routing, ensuring convenient access to batteries. The communications batteries also got very hot, so Mark designed cooling ports for even airflow, an extraction point for the exhaust, and a shaped top-flap to cover the GPS and protect it from the elements, while allowing the antenna to poke out of the back for clear signals.

Easy Access, Airflow and Setup

At the base of the pack, Mark added easy access via a base opening for the GPS apparatus, making it easier to slip the bag over the apparatus (instead of trying to place it in from the top). It also allowed easier access to the battery pack at the base so they could change the batteries out without taking everything apart.

Teams of Varying Size

There was a “one size fits all” requirement for these backpacks, to minimize the daily changes between crews and to keep within the project budget. The issue was that each and every astronaut was different: some women in the team were 5’2” and some of the guys were 6’4”, over 10 inches difference. So Mark designed an all-new adjustable harness that moved on rails and interchangeable waist belts.

As Little Weight As Possible (But Super Strong)

Standard fabrics like Cordura had failed – they were too heavy and melted in the acid rain. So Mark looked to UHMWPEs for a solution and landed on the newest technological innovation at the time: Challenge Sailcloth’s Ultra. It provided water, acid rain, and high abrasion resistance and cut the weight in half. The white color also helped reduce heating effects from the Sun.

Unbreakable

Plastic hardware wasn’t an option. When you’re spending hundreds of millions of dollars and traveling 300 million miles your equipment can’t fail. So AustriAlpin hardware was used in every possible way, ladder locks, slide buckles, and more. The base of the pack was triple-wrapped in fabric, and the frame was aeroplane-grade aluminium alloy.

Color-coding Teams

There were three teams on the mission, each with a different expertise and job. Mark told me, “ They kind of triangulate. So the ground team relays information from the mothership to the communications lead on the surface, and he or she relays that information to the team in the valley. And so that comms lead needs to know who’s who, and be able to understand this from quite a distance.” So he employed Mission Workshop’s ARKIV System and added colored pouches, allowing for a Red Team and Blue Team, for example. He also made sure the pouches had long toggles, so a gloved hand could access them easily, when they were collecting soil and rock samples.

After Idaho, there was Hawaii and Iceland. Mark and Mission Workshop received footage of astronauts disappearing into volcanic terrain with their EVIBs strapped to their backs, and Mark continued to make small improvements.

Mark tells me they’ve only recently been given clearance to share this story. Working with NASA, although a lifelong dream come true, also comes with secrecy and protecting the special innovations you make.

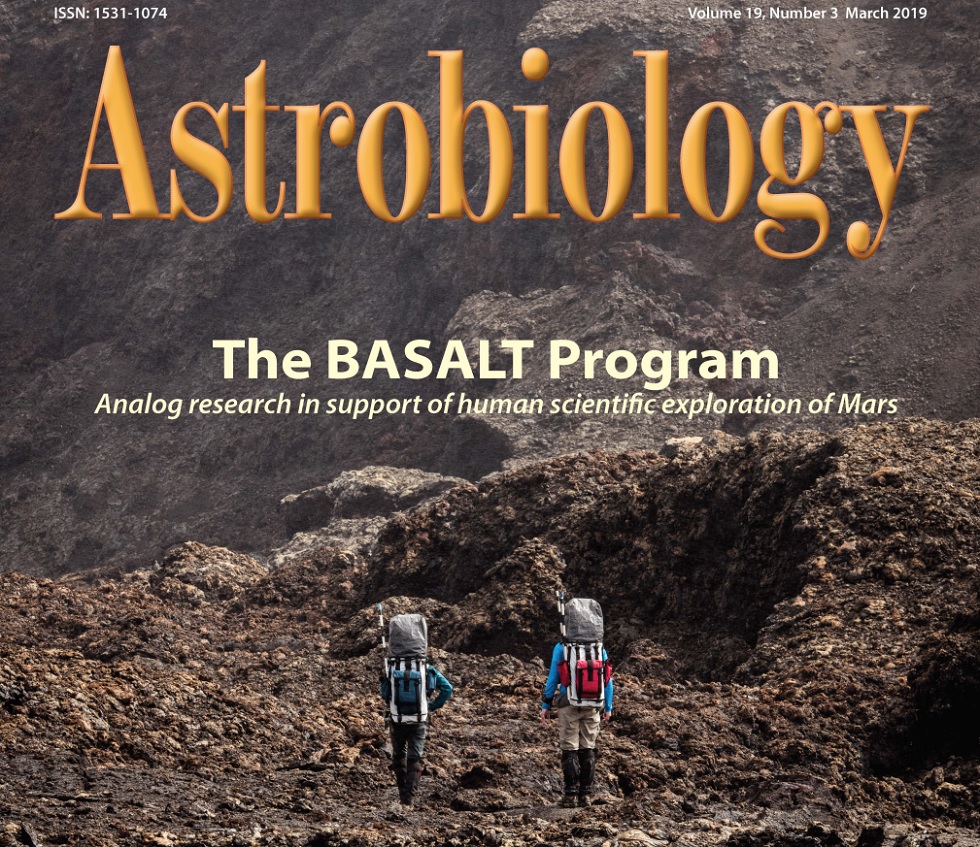

He’s excited to talk about it now. And when I ask him about his favorite moment he gives a surprising answer. “It was making the cover of Astrobiology Journal. You know, because it was something really serious, and taken seriously by this whole world of the science community. It wasn’t the cover of a skateboard magazine or a fashion magazine, you know. It felt like the ultimate street cred,” he laughs.

He also tells me the EVIBs he designed are being used on another mission. There are moon bases to be built and construction work to be performed on the moon, so the EVIBs can be tailored to that scenario too. But that won’t be an issue, I suspect. Not for a self-professed ‘rocket nerd’ like Mark.

As we get off the call, Mark and I play a round of what ifs, imagining what a NASA-inspired pack might look like in the everyday world. It was a fun idea, and so we get our teams together and threw some more ideas around… started to shoot for the stars…

And the rest, they say, is history…

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews