Behind the Scenes of The Arc’teryx Brand

Last week was pretty rad here at Carryology. In between chasing rainbows and talking general Carry awesomeness, we got the chance to interview Dan Green – the design manager for Arc’teryx and Arc’teryx LEAF. Anyone in carry knows who Arc’teryx are and what they’ve achieved not only in carry but in other categories such as gloves and outerwear, even their research into color. So we were pretty excited to get some time with their lead design manager.

We spoke to Dan about a number of various topics and got some really insightful answers back. It’s a great read and something we encourage you all to take five on to read. Anyway, enough gushing, enjoy the interview below…

—–

The Arc’teryx Brand

How much does the Arc’teryx ‘brand’ enter your design decisions? How different would your designs be if you were designing for yourself rather than for Arc’teryx?

The brand’s high performance and high quality expectations drive design decisions here. Our purest design motivations and inspiration come from personal mandate but those must be filtered so we end up with commercially viable, mass producible gear with wide appeal. Designing for myself is different without commercial constraints because I’m making something for a very specific purpose and I’m not paying retail for it. The genesis of Arc’teryx design philosophy is a full freestyle approach to make the ideal thing, but structure and discipline are the only ways to finish something that thousands of people will buy, otherwise you are just making art for yourself.

Company culture

How do Arc’teryx continue to resist the pull towards almost every other generic outdoor brand?

I think we hunt for creative people who will grow when they are pushed to work towards high ideals. Our new GM described this very well as a persistent-growth mindset and I see it manifested in nearly all aspects of our company. It’s just ultimately about doing the right thing at every level. And the right way is always the hardest way. In Design we have to struggle with this daily and try to find a balance so we can actually finish things and get them out there.

I guess on the same theme, Jeff Bezos (Amazon) writes about how most public companies are incapable of “sacrificing this year’s profits to invest in long-term customer loyalty and product opportunities that will create bigger profits next year and for years thereafter.” It feels like you guys manage to do it, focusing on rad product year in, year out. Can you talk a little about the company culture that allows for that? How do you champion R&D projects with unclear deadlines or returns?

We’ve traditionally been a design driven company, but we don’t approach all our design as a seasonal reinvention. While it would be great to revolutionize categories year after year (we’ve done this only a handful of times), we instead just recognize known product parking spots and work to incrementally improve them when we can and sometimes that can take years. The rest of the company is sort of along for the ride, putting a lot of trust in the direction coming from product. Companies that drive from near-term marketing needs for short-term commercial gains will just get half-assed products that they can’t stand on a decade later. Our products need to be worthy of that Bird logo instead of leaning on it. That’s a fine line to maintain as we grow but from historical examples in our space it’s obvious that textbook brand building is the fastest path to mediocrity. We have to do the right thing so we can get asked this same question 20 years from now.

Is there any collaboration with other brands in the Amer stable?

Not too much in product design but that could change where it makes sense to tap into a broader or complementary skill set or technology. There’s more back-end collaboration with Operations and shared systems.

How similar are the designers in your team? Do you guys shoot for consistency or diversity?

There is no prototypical designer at Arc’teryx. If there’s a common thread it’s probably having a hands-on approach but even that is a broad stroke. We’ve got huge diversity in our design and development skill sets that we can cut and paste together to get stuff done. Or we all disagree entirely, start fighting and get nothing done. Captive biodiversity like this is not always a good idea. It’s weird, like a zoo. Or more like Noah’s ark. Quarantine would be useful.

Is anyone in Arc’teryx able to say the full reptile name?

I doubt it! Only a handful of employees can even pronounce the abbreviated company name correctly and I think the majority of people who recognize the brand can’t say the full reptile name. We like it that way. The last thing we want is for anyone to think they understand us.

Innovation

It feels like Arc’teryx softgoods are natively 3D, rather than 2D just translated to 3D. Can you talk a bit about your creative process that lets you think and make such 3D designs?

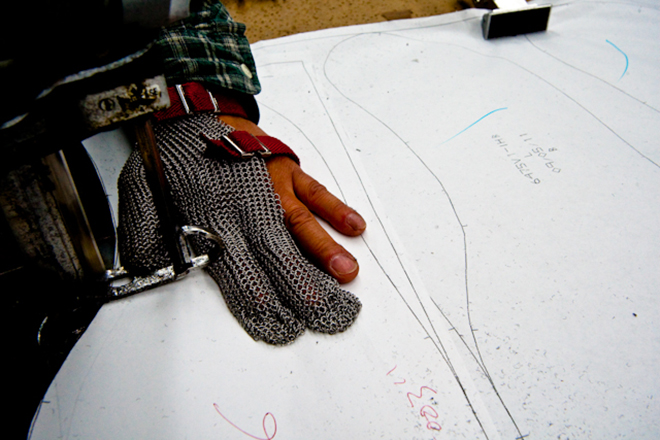

We work with the understanding of realizing a 3D end result. 2D creative steps for visualizing, patterning and shaping are important parts of the process to get us there. Nothing functions two-dimensionally on paper anyway so it’s always speculation. Good ideas are only good ideas when they get built up and work in the field.

Arc’teryx seem to work pretty closely with some top suppliers and makers. Can you talk a bit about those relationships in the creative process?

We often work closely with suppliers to build us the right materials for our needs. Tight brand/vendor relationships are common in the industry. It’s not uncommon to have a dozen rolls of experimental yardage under our tables.

We can imagine lots of benefits to controlling so much of the manufacture yourselves. What are some of the negatives?

We don’t control the manufacturing as much as what we ask the factories to produce. The best we can do in Design and Development is make perfect samples and then push and support factories very hard to build these properly in bulk. Our Quality Control standards are extremely high and we reject everything (raw goods to finished goods) that don’t meet criteria. The downsides are the risks of losing entire production runs to quality. There is lots of trust with our numerous partner factories around the world, no different than all industries with a global supply chain.

Who sets the design briefs? And which customers guide your efforts?

We have a good partnership between product line managers and design managers to drill down into briefs. In LEAF we work closely with handpicked tier 1 users to steer and evaluate our gear, validating everything in the field before we launch it.

What was your journey to where you are now?

I started sewing and building personal gear for caving, climbing and paddling in 1991 when I was seventeen. While hunting down a sewing machine mechanic in Calgary, Alberta in 1998 I crossed paths with Integral Designs and joined them a few months later where I cut my teeth in production until I started as a junior pack designer with Arc’teryx in 2000. I had a few side projects between then and now, but I’m currently managing the design for LEAF, Gloves and Accessories.

Talking carry

Arc’teryx has a fair heritage with carry, including one of the first roll-top backpacks. How does that play into what you do in a general outdoor and winter goods brand?

Packs played a huge roll in defining how Arc’teryx approached design and production. Lots of innovation and tool building with our own factory. Over the years the bulk of the outdoor pack market has shifted from 80-liter backpacking to 45-liter sports, but we’ve maintained our load carriage thinking and applied it to lighter and smaller packages. Packs are a part of each category.

Which other crew do you rate? Others in the carry area?

Osprey is doing very well in the outdoor space and Mystery Ranch owns the Special Operations military space. It’s been impressive to watch these brands focus on their areas and establish themselves.

What carry products are you most proud of? What’s your daily carry?

A few years ago I was part of the Advanced Composite Construction (AC2) pack project to take packs and make them simpler. Though the products weren’t dialed the technology was good and we are still plugging away there and some developments had good spinoffs. One tweak was the laminated suspension in our outdoor Nozone packs and the LEAF Khard and Khyber packs. I’ve done long trips with these packs and they are solid and shockingly light. The simple combination of laminated materials is like plywood construction (several lesser layers combine into a single exceptional layer). I’m still carrying an early version of our new LEAF Khard 30 pack that launched in the Spring of 2013.

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews