The Fabled Craftsmen of Yoshida & Co.

It is a warm morning in Omotesando, one of the most exclusive shopping areas of Tokyo. The sun is beaming through the canopies of Japanese Elms lining Omotesando Dori, laying contrasting shadows and light along the pavement. There is a tangible lack of the usual traffic noise – the same spot on a weekend would be jam-packed with shoppers and cars.

Twenty paces down a narrow lane brings me to the KURA CHIKA YOSHIDA OMOTESANDO store, where I am to meet with one of the fabled Yoshida & Co. craftsmen, Manabu Ando, to learn more about his work.

Inside, the flagship store has a small showcase factory. It is the size of a small office glazed from waist height to ceiling, along one wall, so that shoppers in the store can ogle the products being crafted on site.

Since Yoshida & Co. doesn’t have any of its own manufacturing facilities, it works very closely with around 50 specialist manufacturers across Japan to create its different styles, which number upwards of 100 new designs a year. Each workshop or region has craftsmen with a very specific set of skills that suit a particular style of manufacture. And each and every item produced carries an individual serial number, so if anything ever requires repair it returns to the original craftsman who made it. With this kind of accountability and pride at stake, it’s needless to say that returns don’t occur very often.

"Since Yoshida & Co. doesn’t have any of its own manufacturing facilities, it works very closely with around 50 specialist manufacturers across Japan to create its different styles, which number upwards of 100 new designs a year."

Ando san, one of the few in-house Yoshida & Co. craftsmen, arrives wearing Adidas skate sneakers and Oliver Peoples glasses. He formally bows low, shakes my hand and breaks into a huge grin.

"Each workshop or region has craftsmen with a very specific set of skills that suit a particular style of manufacture. And each and every item produced carries an individual serial number, so if anything ever requires repair it returns to the original craftsman who made it."

Nine years ago, after graduating fashion school, Ando san began working at the KURA CHIKA YOSHIDA Omotesando store as a part-time member of the sales team. It was while watching the manufacture of hand-sewn goods, in the small factory we are standing in now, that he was inspired to become a Yoshida & Co. bag craftsman.

“I was always interested in craftsmanship as I studied clothes making at diploma level. While I was working at the Omotesando store as a sales associate, I was fascinated by how the bags were made and constantly asked one of the hand-sewing craftspeople, Notani san, questions. After a while Notani san realized that I wasn’t going to let up, so she took me under her wing and began teaching me.”

Ando san was dispatched to the manufacturer in charge of the production of the TANKER series to begin formal training under super-strict tuition. He says he was initially worried as to whether he could actually pull it off. However the words of his senior craftsman, Matsuro Ikeda, carried him through, “In any event, you can’t give up. The moment you think that you can’t do it is the moment it is over”.

After six and a half years of grueling training Ando san was moved to the Production Department. He now handles the crafting of samples requested by the design team and the production of exclusive models for the flagship store.

"In any event, you can’t give up. The moment you think that you can’t do it is the moment it is over."

Today he was to show me the sewing process of the TANKER series, one of the most significant series in the PORTER brand produced by Yoshida & Co.

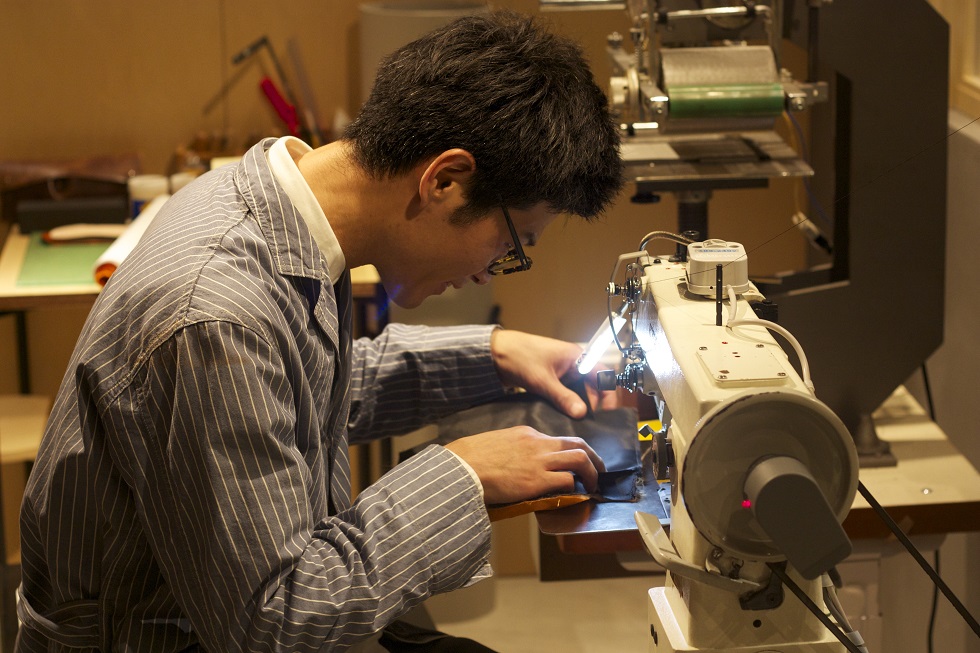

He and the craftsmen of Yoshida & Co. spend a great deal of time totally focused on one particular thing. Ando san has spent most of his time crafting the TANKER series items and takes me through stitching a bag pocket which includes the famous PORTER logo, his hands steady like a surgeon.

“I like to start with the pockets as they are usually the most complicated elements of a bag. Plus they have the company logo on so I take extra-special care to get each one spot-on”.

"I like to start with the pockets as they are usually the most complicated elements of a bag."

When Ando san originally started working on the TANKER series he was only permitted to craft the shoulder strap. That was all he would do, day after day. He would focus every ounce of his concentration on sewing each one, straight and clean, and then sew another and so on.

This style of training is very similar to that of a Japanese martial artist who spends countless hours repeating basic movements in an attempt to attain the Zen-like state of Mushin (or ‘mind of no mind’). Mushin is achieved when a person’s mind is free from thoughts that would normally hinder perfect execution of a task. Its closest approximation in Western culture is our concept of ‘flow’ (or being in ‘the zone’) which is characterized as a state of completely immersed, focused energy or deep focus on nothing but the activity – not even oneself or one’s emotions.

"When Ando san originally started working on the TANKER series he was only permitted to craft the shoulder strap. That was all he would do, day after day."

It’s clear that Ando san goes deep into whatever he is doing. This seems to be a recurring theme amongst Japanese craftsmen: Picking a very narrow field and becoming exceptionally good at it.

The way he talks it seems that he is totally dedicated to incrementally improving his skills on a daily basis. While he is working, he looks as if there is nothing else in the world that, at that moment in time, he would rather be doing – like the outside world no longer exists for him.

"It’s clear that Ando san goes deep into whatever he is doing. This seems to be a recurring theme amongst Japanese craftsmen: Picking a very narrow field and becoming exceptionally good at it."

It was only after four years that Ando san was taught how to make the entire TANKER bag.

“At that time, I was happy to be acknowledged, even just a little bit. All of the work done by the craftsmen is overwhelmingly clean. Of course this may come as no surprise, but a craftsman is somebody who can produce the same accurate results over and over at a quick speed. I was very aware that work had to be clean, precise, and quick when I was making samples.”

And Ando san doesn’t disappoint. He knocks out a bag pocket with startling speed, taking extra special care, of course, when stitching the famous PORTER tag on.

He is arguably one of the best in the world at what he does and yet he is very humble. The conscious continuous daily honing of his skills is testimony to him not resting on his laurels. When I ask about what drives his attention to detail and makes him keep pushing himself, he states that he simply wants to do his very best so that the person who buys the bag he just made will love it and make it a part of their lives for a very long time.

This is probably the biggest factor contributing to Yoshida & Co.’s success and why the company is held in the highest regard. Each of the craftsmen seems focused not just on making a great product but on what that product will mean to the end user. A focus that projects beyond the product itself. A desire to create a product in such a way that the end user adores it just as much as the craftsmen who made it.

"Each of the craftsmen seems focused not just on making a great product but on what that product will mean to the end user."

This exemplifies how the philosophy of Kichizo Yoshida, the founder of Yoshida & Co., which has persisted in the company for more than 80 years, is still having a huge positive impact upon internal culture. It is this ability of staff to care so very much that will, in my mind, help Yoshida & Co. continue to make such great products and flourish for years to come.

Here’s to spreading the love. Heart and soul into every stitch.

This article was written by Richard Bolus: Bellroy Special Ops, linguist and polite Englishman who has an annoying ability to see the bright side of things in life. He likes reading, taking long walks at sunset and his favorite color is blue. He’s also ex-British Army and taught martial arts to the Tokyo Riot Police.

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews