Game Changer: Let’s Talk Dyneema Bonded Leather

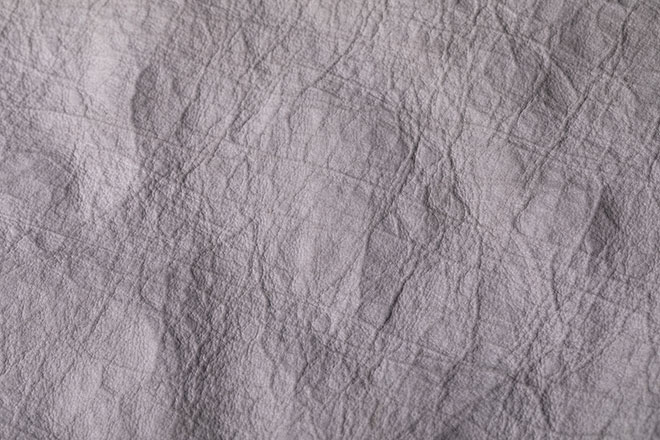

Leather offers an appealing combination of toughness and beauty. But as materials go, it’s certainly on the heavier side. And if you want to reduce the thickness to cut down on weight, you also have to make sacrifices in strength. But what if you could have strength, beauty and reduced material weight?

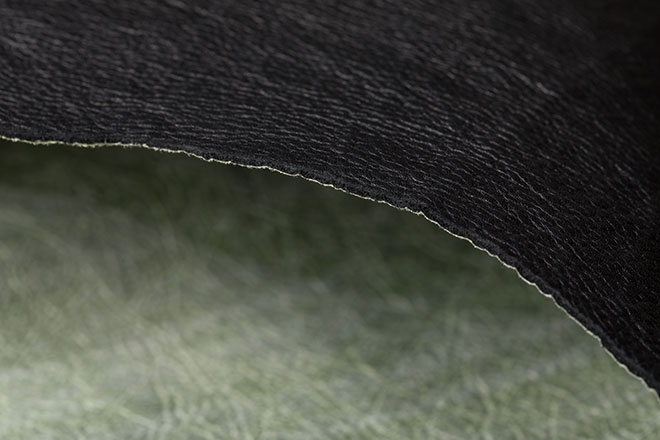

Enter Dyneema Bonded Leather, a new material created through a collaboration between ECCO Leather and DSM Dyneema. A game changer that bonds Dyneema Composite Fabric to thinly skived high-grade bovine leather. Panos Mytaros, CEO of ECCO Leather, tells us more…

Let’s talk about the ‘inception moment’, how did this new product come about?

Our R&D tanning facility in the Netherlands has been hosting international open development events for a decade. Over the years literally hundreds of designers and developers from the world’s best brands have joined us for a live leather-making event. Probably the biggest creative leather making event. It is called the HOT-SHOP and our alumni include folks from Apple, Alexander Wang, Helmut Lang, adidas, Nike, Stone Island, Rolls Royce, Rick Owens, and many others. One of our recent participants was Conroy Nachtigall of Veilance fame and he, together with Sruli Recht and others from our in-house team, suggested the match between ECCO Leather and Dyneema.

What were the biggest challenges along the way?

Our tanning ethos is that leather must behave, feel and look like leather. We are not big believers in gluing stuff on the surface, overspraying, or any other process that compromises leather’s natural character.

The biggest challenge was how to combine two materials that don’t have any single similarity. How to bond the leather to Dyneema and then create one single material out of these two, leatherising the new material.

What excites you most about this?

What excites me the most is we finally combined many qualities in one material. Lightweight/strong and still with a cool leather look; not a plasticised artificial substance.

At ECCO Leather we absolutely love a challenge. We often work in an improvisational style where we remove “no” from our development vocabulary. We don’t even say “yes, but…”. We say “yes” and then we work diligently to figure out the how. We’ve done that in several areas over the years. Shine leather made without the patent process, heat-sensitive leather, transparent leather, glow in the dark Yak hide…. So the Dyneema project was extremely tempting from the start.

Is there a particular product category that this was designed for? Who was the target for this one?

Well, I’m not sure there was a target per se. Lightweight, thin, extremely strong tear-resistant pliability lends itself to all categories depending on how it’s deployed, but it’s natural to think of bags and outerwear in that mix.

“Lightweight/strong and still with a cool leather look; not a plasticised artificial substance.”

What specifically made the high-grade bovine hide the perfect match with Dyneema in this product?

Bovine is a versatile skin and the Dyneema project represents an elite quality level, so premium material on our end was a given. We knew that tanning in softness would be one of our objectives to counterbalance Dyneema’s non-woven filament based properties and bovine material has a proven track record in this regard.

Assuming the leather is skived down to approximately 0.3-0.4mm, what fundamentals did you need to overcome in the secret tanning process? Abrasion, stiffness, hand feel?

We could tell you but we’d have to shoot you. No, seriously, the process makes significant use of the secondary tanning steps. Those tanning stages that are done after the bonding process has been completed. These stages include several conventional tanning phases and a few unconventional ones. The exact sequence of these phases and their duration plays a big role as well. We knew we could rely on Dyneema for the strength and we knew this would allow a thin skive/split – so softness and real leather hand feel were important to us as mentioned above.

What was the most difficult part of the process to get right?

Finding the right way to bond. After that the leather is stiff. Normal bonded leather is stiff. We wanted to create a soft and cool-looking leather. This is why Dyneema Bonded leather is made in a tannery with additional processes to just bonding.

“We knew we could rely on Dyneema for the strength and we knew this would allow a thin skive/split – so softness and real leather hand feel were important to us.”

What sizes would the material be available in?

It’s leather. Sides from 20-25 sf.

Is there any stretch to the lamination? Will there be varieties that do offer some stretch?

Dyneema’s non-woven structure disallows stretch since there is no “bias” (there is no weave to rotate). However, this is considered a good thing in the main applications.

Does the leather side have enhanced abrasion resistance, or is it typical leather levels?

The surface is leather and the properties are the same. BUT…the Dyneema Bonded leather is one new material. The combined material has better strength and better abrasion resistance than any other equivalent leather.

How much stronger is it than regular leather? Tear, tensile, or abrasion etc.?

It is much, much, much stronger. At the same thickness, it is many times stronger than our strongest non-Dyneema qualities (Yak for instance). But Dyneema rightly reserves the right to test these measurements in the finished product because leather-handling and finished goods production techniques can enhance or diminish the ratios. Suffice it to say it is incredibly strong.

“The combined material has better strength and better abrasion resistance than any other equivalent leather.”

How accessible will this material be to designers and brands wanting to utilize it? Can we get a sample?

Folks are invited to contact us via our website. We love a challenge and are looking forward to seeing the material used in cool ways.

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews