Carry Geeking: Techlite backpack straps

Sometimes good design gets forgotten. Not necessarily unappreciated, but we tend to forget about the people/designers who have created something that we might be enjoying every day. What you’re about to read is a great example of someone wanting to share the stoke – which makes us feel all warm and fuzzy. 🙂

The below is an email that got sent to us by a reader who wanted to share his enjoyment for a product, as well as give props publicly to the design team. Generally, it’s not something we’d publish, but there’s some good quotes and insight to be shared. The reader, who has asked to remain anonymous, is a bag designer himself and was so impressed with the product, he felt he needed to share it with us. Below is the article, slightly edited, but mostly in its raw form.

—–

I bought myself a Columbia Manifest II, with Techlite straps a while back – price was good, and the brand is dependable. When I reviewed it at the store, I was a little thrown back by the straps. I have seen everyone in the sporting industry address strap styling; memory foam, mesh overlays, fabric breaks, non-slip PU, molded insides, but these Techlite straps were different.

The whole strap was molded, (co-molded to be exact) with a mesh panel sandwiched in the middle. The molded part of the strap, a foam type material, was sturdy and soft. The straps were colored in the accent features from the pack. And, there was a nice soft but tactile texture molded into the resin. My first thought, “This isn’t going to feel good”, but after 2 weeks of traveling, the straps felt GREAT! The resin-foam material conformed to fit me, and the mesh panels never let the heat or sweat build up under them.

Other things to note about the straps, they were fitted with load adjusters, waist belt and a nice air flow back panel. The main body material of the pack was sufficient and the pack was equipped with side compression straps to keep the contents from moving all around in there.

Next step, find out how it was done. So, I called (many annoying times!) and got a hold of Tom Hinkle, Sr. Product Manager at Columbia Sportswear Company. Tom was the Sr. PLM Equipment and Accessories product manager when these straps were created.

Tom’s description on Techlite goes like this:

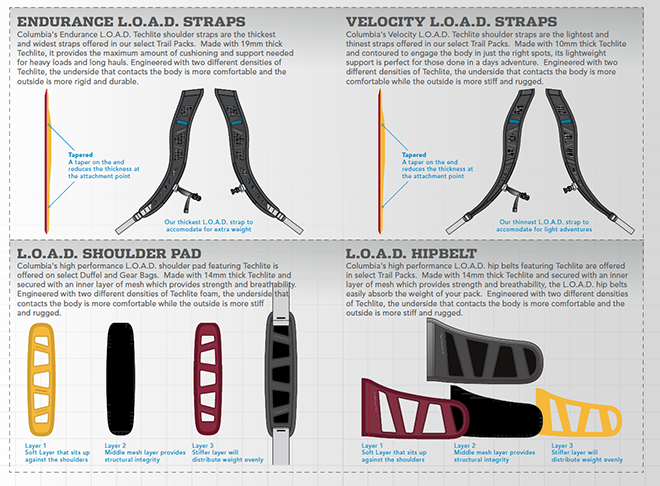

“This in-house innovation was put together by the great minds of Mark Gingo, Senior Designer in Equipment, and other talented folks in product development and the footwear team….ya, shoes! The Techlite LOAD (Lightweight-Open-Air-Design) is a patented process delivering lightweight/breathable backpack & duffel straps & hip belts. The straps are manufactured in a FOOTWEAR factory that specializes in performance foams and molds. They are made using a co-molded process where 2 layers of Techlite (patented) foam are sandwiched over a lightweight scrim mesh, which provides strength without weight. This process allows us to vary the durometer of foam on the underside vs. the top side. What that means is we can have softer/more cushioning foam against the body and a bit stiffer, more durable foam on the outside.”

I also got to talk to Mark Gingo, the innovative mind behind the straps. His main objective? How to create a strong, lightweight and conforming backpack shoulder strap.

Mark’s concept came from none other than Concrete. But, what makes concrete strong? Rebar, the metal reinforcing bar that provides flexibility and strength to most concrete foundations and slabs. For an in-house designer, a big advantage is the ability to source within the company. Mark detailed out his concept, and went to the footwear development team over in their innovation lab. Using Columbia’s proprietary shoe foam compound and a durable Mesh to act as rebar, Techlite straps were born. Columbia have since incorporated this technology into 3 categories: Multi-Day Outdoor, Velocity Outdoor and Mass or Back To School (BTS).

There you have it, great functional innovation and a good step forward into something new for the outdoor industry. I would like to give another shout out to the Columbia team – working as an in-house designer, depending on the company you work for, you get the benefit of financial resources that an independent designer or business owner doesn’t. But, the other side of it is you don’t always get the acknowledgement from your peers in the design community because you’re in-house. Congrats on impressing this designer, and hopefully impressing a bunch more of the people who buy your brand.

—-

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews