Fjällräven Samlaren | Giving Life to Surplus Materials

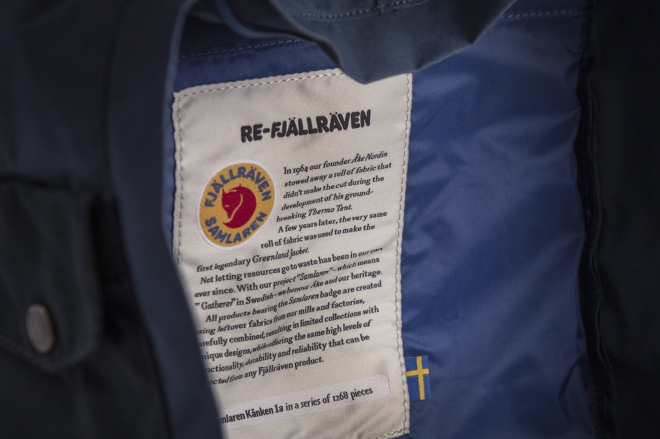

As the story goes, in 1964, Fjällräven founder Åke Nordin was developing his groundbreaking Thermo Tent and he tried using a fabric but it did not quite make the cut. He stowed that roll away and years later, pulled it out of storage, and used it to make the first Greenland Jacket. Fjällräven, the Swedish outdoors company, has had a long history of environmentalism and sustainability. Some examples include using recycled materials, switching to fluorocarbon-free treatments in 2012, and working with the Fair Labor Association to promote and improve workers’ rights and conditions.

Earlier this year, the brand launched its Samlaren initiative. This aims to bring new life to surplus materials by repurposing them into practical products. The name, Samlaren, is Swedish for “the Gatherer”. By taking scraps and leftover materials off the cutting room floor, Fjällräven is bringing them together to form unique collectible products that will be released in recurring and limited capsule collections.

When the company realized they had shelves full of excess material, they set out to find a way to give them purpose. This is the reverse design process that companies take. Usually, a product is created to meet a consumer’s need or demand. In the case of Fjällräven Samlaren, the company wanted to create products to use the materials. With that starting point, they set out to create products that still met the same quality and usefulness customers expect.

One of the most resource-intensive parts of clothing and bag creation is the actual production of fabric. It uses a large amount of water, chemicals, and power and produces emissions and by-products. By using materials that are already in their mills and factories, new products can be produced without having the cost of production go to waste.

The first collection is made out of surplus G-1000 fabric. It includes the classic Greenland jacket, Kånken backpack and updated versions of the tote bag and even a cap. The designers cleverly employ color blocking to add a touch of playfulness but also subtly signal the items are upcycled.

The Fjällräven Samlaren Jackets come in three colorways for men and three in the women’s cut. The Kånken backpack is slightly larger than the original model. It features padded shoulder straps and several pockets – open, zippered, and with button closures. There are four colors to choose from. Similarly, the Totepack is also available in four colorways and has a simple design with an open main compartment. A small buttoned inside pocket provides quick access to small items. Lastly, two caps round out the collection and feature contrasting shades in the bottomside.

Many companies are taking sustainability and conscientious production more seriously recently. But this has been top of mind for Fjällräven throughout the company’s history. With advances in material production and recycling processes, consumers no longer have to make a decision between buying green versus a quality product. Companies have proven that products using recycled or upcycled components perform just as well as those using virgin materials.

However, Fjällräven’s ultimate goal, naturally, is to become so efficient in their design, patterning, and material production that they no longer have excess or leftover materials that need a home. Ironically, if the brand reaches this goal, the Fjällräven Samlaren project will become obsolete. But they’ll be an even better brand for it. Respect.

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews