The Best New Fabric Technologies from OR

Will Watters is the co-founder and creative director of Western Rise, a Colorado-based brand making some of the world’s best everyday performance clothing. And so when he offered to report back from OR, since, you know, he’d be combing the floor for the newest and best innovations anyway, we jumped at the chance. Here’s his report. Enjoy!

Outdoor Retailer is a space for the world’s top outdoor and performance brands to showcase their newest gear and technology, but unknown to most it is also the top US sourcing destination for the most technical innovative fabric, trims, and components. Deep in the basements and corners of Outdoor Retailer hide yarn spinners, fabric knitters and weavers from all over the world – true textile innovators who are creating the future of performance clothing and bags.

For four days every January, August, and November, product designers and developers walk miles of trade show halls having meeting after meeting with suppliers to combine yarns, fabrics, trims and hardware to create products that will reach the market years in the future. From custom-built yarn-spinning to unique fabric systems, the future of textile innovation was on display at Outdoor Retailer in Denver this January. Great materials alone do not make great products, but a glimpse into fabric innovations can help us to imagine the gear of the future…and it looks pretty incredible. We’ve rounded up some of the best below…

The Woolmark Company introduces OptimJam Double Weave

What it is: The Woolmark Company presents a 100% wool fabric with two very different surfaces. One face is smooth like a traditional shell, while the other side is soft, lofty and brushed. This innovative double weave fabric provides maximum insulation whilst minimizing fabric weight and retaining all Merino wool’s natural properties such as breathability and moisture management. The outer face of OptimJam Double Weave is constructed with a high level of thread density in warp and weft using fine Merino wool yarns that have been stretched, but not set, during Optim processing. It is only when the fabric is wet-finished that the stretch is released causing the yarns to contract, thus leading to an extreme tightening of the fabric structure and the creation of the immensely dense fabric that is naturally water resistant.

Why it matters: By this point, most of us are familiar with the incredible qualities of Merino Wool – odor-neutralizing, temperature-regulating, soft, natural performance. OptimJam Double Weave takes this a step further by using Optim technology to create one 100% wool fabric that performs like two bonded fabrics while retaining all of the natural benefits of Merino wool. One fabric with a face that is dense, naturally water resistant, durable and highly breathable and a back that is lofty, soft, moisture wicking, and warm.

What’s the future: High-end, natural, casual jackets that perform better than the top synthetics without the use of glue, membranes, or linings. Jackets with a natural look and feel that keep you warmer, drier, and resist odors and stains.

TORAY introduces The TORAIN System

What it is: With the success of TORAY’s 3DeFX+ active insulation (Patagonia, Western Rise, KJUS, KUIU), TORAY created a new program called TORAIN with ENTRANT Technology. This performance garment system utilizes a proprietary material to create its highly breathable (20K), stretch ENTRANT membrane, as well as a fully engineered seam sealing system to create a seam-sealed shell that surpasses the 10-year durability mark in testing. Paired with TORAY’s 3DeFX+, TORAY’s TORAIN system can create one of the most highly breathable, technical, packable, stretch insulated shells available.

Why it matters: TORAY’s TORAIN combines two industry-leading technologies into one perfect system that is built to last and provide superior protection from the elements. TORAY’s 3DeFX+ set the bar for active insulation, creating the most innovative product in more than a decade allowing breathable, stretch fabrics to be used instead of down-proof fabrics. Combining this with the highly breathable ENTRANT shell fabric creates a system that is unrivaled for active, insulating shell jackets.

What’s the future: Breathable active insulation will be paired with highly breathable protective shells to create innovative new all-in-one jackets that shed heat and humidity better than ever before. Warmth without overheating is finally achievable without a layering system.

Suedwolle introduces Wool Shoe Yarn Selections

What it is: Wool has been showing up in shoes from Allbirds to Adidas over the past few years, and demand doesn’t seem to be slowing any time soon. Wool shoes are light, comfortable and breathe extremely well. Wool is also naturally odor resistant and thermoregulating which is an added bonus in shoes. Suedwolle recognized the growing demand for wool yarns for shoes and vastly expanded their offering. In fact, it was interesting that Suedwolle sees such a large market need that they focused their entire show on footwear.

Why it matters: With more options for knit and woven wool footwear yarns, there will be a wider range of wool footwear options. Footwear that doesn’t smell, doesn’t stain, breathes like a dream and regulates foot temperature.

What’s the future: More than likely, if it’s not the case already, your favorite shoes are going to be made from wool. Outdoor, lifestyle, and travel shoe brands are all focused on bringing wool options in the near future.

Polartec introduces High-Density Knit NeoShell

What it is: Polartec® has had incredible success with its NeoShell® membrane in the past, especially with its woven, durable faces. This show they introduced a dramatic change to their proprietary technology. The new Polartec® NeoShell® with a high-density knit face is an engineering breakthrough for waterproof breathable fabric technologies. Dynamic air exchange at the surface provides unrivaled ability to stop water and wind without restricting the release of excess heat and moisture vapor. This high air permeability provides the unique benefit to function as a durable protective shell with advanced wicking capabilities to keep moisture vapor moving away from your core. The invention of Polartec® NeoShell® revolutionized waterproof breathability capabilities by lowering the internal pressure required for vapor to permeate the membrane. This releases moisture more easily and keeps microclimates circulating with cool air faster than other protective materials. Polartec® has now combined this NeoShell® membrane with a high-density stretch knit to create the future of waterproof-breathable membranes.

Why it matters: Polartec® has shifted much of their development from stiffer, strong, woven face fabrics for their 3-Layer shells to supple, knit fabrics with lots of stretch. Normally, this would mean a decrease in durability, but by building low-denier, high-density knits, they have actually created soft, supple knits with higher abrasion resistance than the woven faces that they were using in the past. Added benefit – these shells stretch – A LOT.

What’s the future: The new high-density knit face NeoShell® completely blurs the line between hard-shell and soft-shell. Jackets in the future will move more with the body, perform better during activity, keep you dry, and pack down to nothing. This technology allows people to rethink how they dress. They no longer need to consider keeping their shell in the bottom of their pack just in case, they can keep it on for the widest range of temperatures.

FlyingTex introduces Self-Healing Nylon Ripstop

What it is: FlyingTex introduces a self-healing treatment for high-denier nylon ripstop fabrics. Thanks to a proprietary surface treatment, FlyingTex has created a fabric that can repair itself from punctures with light friction.

Why it matters: With light friction to the fabric from your hand, FlyingTex’s proprietary new fabric technology can repair punctures while maintaining its water repellency. As a down-proof fabric, this fabric can repair itself after large down feathers work their way through the fabric or when a sharp item has punctured the fabric. This reduces the need for patching jackets or bags that have been damaged, and makes for a longer-lasting garment or bag.

What’s the future: Less duct tape on jackets on the mountain and longer lifespans for thin down-proof jackets and bags.

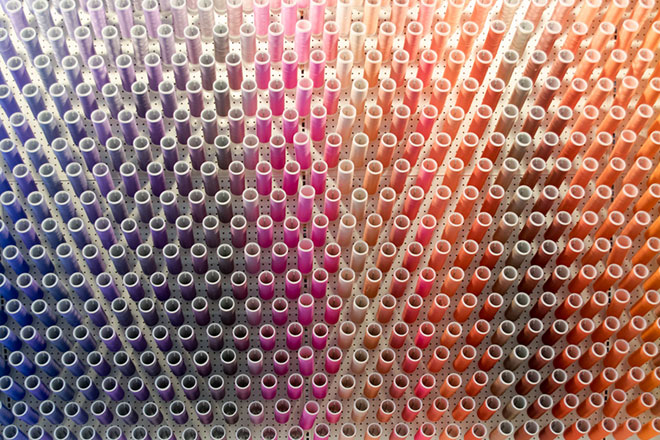

e.dye introduces Waterless Color System

What it is: e.dye is a color system for solution-dyed Polyester that uses no water, no harmful chemicals and results in the most durable and brilliant colors in synthetic textiles.

Why it matters: The dyeing process for fabrics is highly water intensive, with each yard requiring up to 3 gallons of water in the dyeing process on average. With over 3,800 colors and a sophisticated color-matching process, e.dye represents a paradigm shift in textile dyeing, because they actually put the color inside the yarn. This means no harmful dyes in waterways and no wastewater to treat.

What’s the future: As this technology becomes more accessible to a wider variety of fabric mills, textiles, and brands we will likely see an increased focus on lower impact fabric for brands who care about investing in eco-friendly technologies. It is a step in the right direction that hopefully more fabric manufacturers can move toward.

CORDURA® Brand Introduces Konbu-N

What it is: The name Konbu comes from a dried Japanese kelp, konbu, which has a similar hand or appearance to Konbu-N. Konbu is a unique development that requires a proprietary high-tech processing technique to make CORDURA®’s 500D CORDURA® Nylon fabric look organic and natural. The fabric becomes stiff and can stand alone in dry air, and becomes softer and more supple with humidity.

Why it matters: CORDURA® has created a way to give a highly durable, highly technical fabric made for bags a unique, natural look.

What’s the future: Bags and packs made with CORDURA®’s Konbu can transition between outdoor, travel, and everyday life without looking out of place. The new material innovation gives a natural, organic look that is welcomed in the world of technical fabrics.

A big thanks to Will for the insights! And folks, if you’re on the lookout for performance clothing that can transition from park to plane to pathway, we totally suggest checking out his brand Western Rise, he and his team make some awesome gear!

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews