Green Guide: How Brands Are Working Towards Sustainability

Welcome back to part three of the Carryology Green Guide, a four-part look at what it means to carry sustainably. If you missed part one, we took a sustainability crash course. Then in part two we traced a single bag from its raw materials through to its end of life to find out what’s unsustainable about the way things are being done now. In this instalment we talk to sustainability innovators to get a better understanding of what the industry is doing to improve.

Choosing your religion

Before we jump in, let’s set the scene. Thanks to this series I’ve had the opportunity to speak with all sorts of environmental brains, from designers to fabric mills, scientists and NGO’s. Over that time I’ve been struck by two recurring thoughts. Firstly, it’s exciting to hear how much effort is being invested by some very smart people. Secondly, as you’ve probably noticed, the range of sustainable responses coming from the different brands has been incredibly varied which can become incredibly confusing. And you might be asking, if all these people are working towards the same goal, why isn’t there more unity?

A question that we often get asked here at Carryology is “what makes a bag sustainable”. It’s a good question, but it assumes it’s possible to simplify the vast range of issues that impact sustainability into a single measurement. You might think (like I did) that scientists might have come up with a concise way to measure a product’s sustainability. Sadly it’s not that simple. According to Dr Alice Payne, Associate Professor from Queensland University of Technology “Each issue has its own community of researchers examining it, often from very diverse fields with different methodologies”.

So each scientist can tell us about the issue they research, but they aren’t responsible for comparing or prioritizing the different issues. As Dr Payne puts it. “There are no clear cut answers as to whether one should focus on worker welfare, or reducing carbon, or water pollution. What is deemed to be of primary importance will be different for everyone. No brand can do everything at once, they have to start within the scope of what’s possible for them and build out from there – hence the stories you will read about on how they are addressing sustainability will be as diverse as the brands themselves.”

The range of stories we’ve chosen to share is a small but important snapshot of that diversity.

Better Materials (Econyl)

Italian company Aquafil had spent almost 50 years building a reputation as a supplier of quality virgin Nylon, when President Giulio Bonazzi felt a change in the winds. He knew that the current system was unsustainable and he wanted the business to evolve from linear to circular, a supply loop that indefinitely recycles it’s raw material. So in 2011 he launched a new brand, Econyl, which would be entirely devoted to developing new technologies for recycling. Today Econyl yarns are being used by major brands such as Finistere, Outerknown and Adidas. They even made international headlines after Meghan Markle was spotted clutching an Econyl / Prada bag. But other than just big brand attention, what makes Econyl different from other PET fabrics is that it promises to realise the possibility of a circular, or “cradle to cradle system” for synthetic fibres.

Currently the process to make Econyl yarn starts with the same post or pre consumer waste used to make many other fabrics. Like all recycled fabrics this helps lessen waste streams and avoids reliance on fossil fuels. But it’s how these materials are processed into a yarn that differentiates Econyl. Currently it’s most common that PET fabrics have been made using a mechanical process which slightly degrades the fabric each cycle. This system of downcycling has a limit, eventually the material can no longer be recycled. Econyl uses a chemical recycling that has no degradation issues. Hypothetically a single nylon bag could be made and remade indefinitely. The company is now working to encourage designers to develop mono-material products or products that are easily separable. That way, once your bag is dead it could be directly inputted back into the system without any loss in quality.

Econyl aren’t the only people to be chemically recycling plastic into yarn, but they claim their process is unique. Their plant also boasts a closed loop water system and the excess steam energy generated by the plant is used to heat water at a nearby water park, which sounds fun.

Better Design (QWSTION)

Like Econyl, the team at Qwstion are also working toward a circular future. They even developed their own circular material, a new plant based fabric dubbed Bananatex. With their new pack cloth ready for production, the team then set about pushing their design practice to create the most circular range of products possible. This meant a lot more than simply reworking old ideas using more environmentally friendly materials. The new design process prioritised sustainability at every step of the journey.

Firstly, Qwstion works with a material pallet that doesn’t look anything like that of a standard bag. This in itself forces designers to work differently. Before drawing begins the bill of materials is intensely scrutinized both upstream and down to reduce it to the bare minimum. Upstream that means searching for the most efficient supply chains currently available. According to Creative Director, Christian Kaegi that research alone can take up to 3 years. Looking downstream the materials must be both fit for purpose and have a clear end of life strategy. The majority of the materials used by Qwstion are naturally circular, in other words 100% biodegradable, including the dyes and coatings. If a material must be used that isn’t biodegradable, the designer must consider how it will be separated and recycled.

Another distinguishing aspect of the sustainable design process is balancing the functional efficiency of a product. Once sustainability is properly considered there’s a shift in the dynamics of the typical cost benefit analysis that goes on whilst designing. Sustainability forces designers to decide what elements are really “fit for purpose”. Does a school bag really need to be waterproof if the coatings required are the only unsustainable element of the bag? Does a tote need a zip if it means the whole bag can’t be recycled? These value judgements have no right or wrong answer, so it’s safer commercially to include all the features. Sustainable design challenges the designer to give the customer exactly what they need for the intended purpose and nothing else. It’s far trickier than simply giving them everything.

Better Models (Bergans)

As we’ve explored throughout this series the challenge for brands isn’t as much about creating sustainable products as it is about building sustainable supply chains. As consumers play one of the largest roles in that chain, brands like Bergans are considering new ways to connect with their audience. According to Sustainability Manager Yngvill Ofstad “changing consumer models and buying habits is the greatest challenge”. And to meet this challenge Bergans are beginning to put their theories to the test. “We know the consumer is going to change, and we think the best way to get ready is to test ideas”.

One such test is a subscription model which they used to release their latest Spinnova collection. Instead of buying a bag, customers subscribed to have use of the bag. If anything breaks, simply send it back and get a fresh one. Don’t need the bag anymore? Return the bag to Bergans where it can be 100% recycled into new yarn, ready to be made into another product. The supply of the product therefore becomes circular instead of a linear chain. Whilst the Spinnova program has only been in testing for a few months Bergans have been testing this model with childrens clothes for almost two years and have found some unexpected positive side effects.

Yngvill noted that the subscription model created a closer customer relationship with better communication, and customers were reporting their own up sides. The new model reduced the need for storing unused items, disposing of them, or the hassle of second hand sales. And if a customer’s needs changed they could easily swap for an item that was better suited. An obvious win for parents with fast growing children.

Bergans also found that the change in how they provided products changed how they designed products. In order to keep gear in circulation longer they began to invest in more durable materials that would otherwise be too expensive. Products were also designed to be more easily repaired and refurbished. Most importantly the products could be designed to be recycled as efficiently as possible. By creating a system in which products can be easily dismantled and sorted, both the quality and value of materials can be maintained throughout the cycle.

Better Accreditation (Climate Neutral)

Another challenge for brands is communicating these vast reams of sustainable information to consumers. It’s unreasonable to think that all of us will fully research the full complexity of the various issues before we make a purchase. So it makes sense that carry needs some form of accreditation system to help us make better informed purchases, like in the food industry.

In 2019 Peak design teamed up with Biolite to launch a new accreditation program that aimed to make things clear and simple for everyone wanting to fight climate change. As you may have read previously, Climate Neutrals strategy is to assist brands in neutralising their carbon emissions, then to clearly identify these carbon neutral brands to customers. All in order to halt the oncoming disaster of a planet that’s getting hotter. Whereas many environmental accreditations become incredibly complex and unwieldy by trying to address everything, by simplifying their mission to a single issue Climate Neutral has been able to develop some powerful tools.

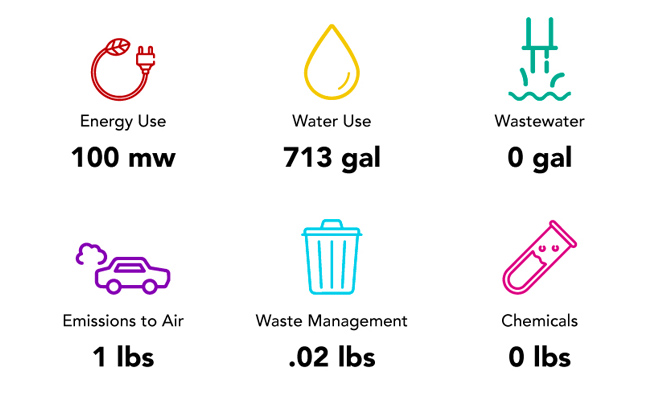

For one, auditing a business using the Climate Neutral calculator takes days instead of weeks. The footprint calculator they’ve built crunches real time financial data to quickly and thoroughly calculate the full carbon footprint of a brand, from cradle to customer.The level of detail is impressive, even including things like heating for the company offices. All of which is boiled down to a single metric: tons of carbon emitted.

That measurement is then used to both identify areas of improvement and to purchase carbon offsets. So once you see a Climate Neutral sticker on a product you know that it has net zero carbon emissions. Sure, it would be better if products had gross zero emissions, but as CEO Austin Whitman points out this is probably impossible. “You can’t solve the problem exclusively through reducing your carbon footprint, nor can you reduce it exclusively through offsets”. What’s so clever about the Climate Neutral system is that it encourages both. Customers know that a company is paying to offset the carbon they do emit and this payment incentivises them to find new methods of reduction.

Theoretically the Climate Neutral approach could lead to brands developing materials that reduce emissions but are detrimental to water pollution or other issues. This is a decision that Austin is happy to make “emissions are the largest globally unregulated environmental problem” and “we’re not going to have to worry about polluting water if there is no water, and there will be no water in some parts of the world if we face 3°C temperature rises”. Personally, given the devastating bushfires fires in Australia this year I tend to agree with Austin’s assessment.

Better Cooperation (HIGG)

Whilst sustainability can still be a confusing topic now, ten years ago things were even more of a headache, so much so that it drove the unlikely duo of Patagonia and Walmart to partner up. At the time larger brands were tackling the problem by spending huge amounts on environmental audits. Each brand’s audit was written by a different team with a different approach. As a result the findings weren’t standardised. It was as if they were written in different languages, making it a nightmare for brands to cooperate. Results couldn’t be directly compared, plus with each brand having its own vested interests in one fibre or another, it was hard for anyone to be impartial in their judgements. All of which lead to a lack of real action. In 2009 Patagonia and Walmart teamed up to find a way for the industry to work together. They launched the Sustainable Apparel Coalition and three years later, after the SAC had gathered a coalition of 60 other major brands and manufacturers, they launched the Higg Index.

The Higg is many things but primarily it’s a way for brands and manufacturers in the supply chain to collect and share their sustainability knowledge. A major focus of the HIGG is a tool they call the Material Sustainability Index (MSI). The directory of 90 materials captures and compares data on each material which is then calculated into a sustainability score. Designers and brands can use the index to quickly compare material options and find the most sustainable. The calculation that goes into the score aims to be as holistic as possible by equally addressing 5 “impact areas”. Global warming, Eutrophication, Water scarcity, Fossil Fuels and Chemical impact. You can even use the MSI for free, check it out here.

Whilst HIGG is still a work in progress it’s an impressive tool. Not only does it allow brands to easily identify areas for improvement, it creates a common denominator that helps unite brands’ efforts. And although right now HIGG is primarily a tool for industry, this year they have announced they are working towards a system aimed at better informing customers.

Thanks to everyone who donated their time and insights for this story. Stay tuned for our final part in the series where we talk about what you can do to help!

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews