Exploring Dyneema :: Interview With Noud Steffens

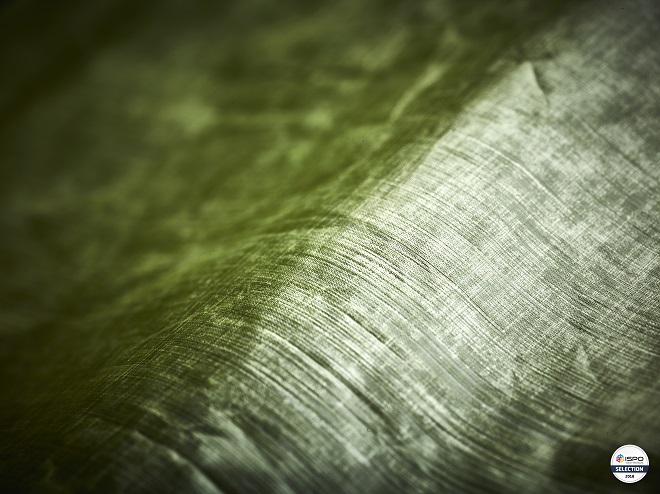

The name DSM may not be instantly recognizable, but one of the company’s key products certainly is. DSM is the inventor and manufacturer of Dyneema, a premium brand of Ultra High Molecular Weight Polyethylene (UHMWPE). To learn more about what the company refers to as the world’s strongest fiber, we got in touch with Noud Steffens, the Global Business Director for DSM.

Can you describe your role working with Dyneema?

I’m the business director responsible for developing lifestyle and sportswear markets. So we do developments in denim, sports footwear and apparel, bags, and all these kinds of products. It’s a global initiative from Dyneema.

You’ve been working with Mike Lelliott at Saint. Can you tell us more about that?

Mike is one of our really innovative partners with our denim developments. He’s working with some of the fabrics that we have developed together with Berto, and using these fabrics to position his motorcycle denim brand.

It’s exciting work. He’s starting to get a few garments back that unfortunately have been in crashes, but they’re looking amazing. It looks like they’ve saved a lot of skin already.

I think he’s doing great things and really helping us to get the message out, and changing how people see protective motorcycle denim. He’s leading the movement of using this strongest single layer denim in the world.

Do you see the fashion market and the blending of fashion and performance as the biggest area of growth for Dyneema?

Yes, that’s actually how we look at it. That’s what we want. We are the new fiber, so we can bring something new to the industry, and bring in the next generation of innovation.

The Dyneema most people in carry are familiar with is the non-woven Dyneema, with maybe a PET film facing. It’s quite crinkly, and more like sail cloth. What you’re doing with Mike has much more pleasant hand-feel, much more subtle use of the fabric. Is that one of the big extensions for you?

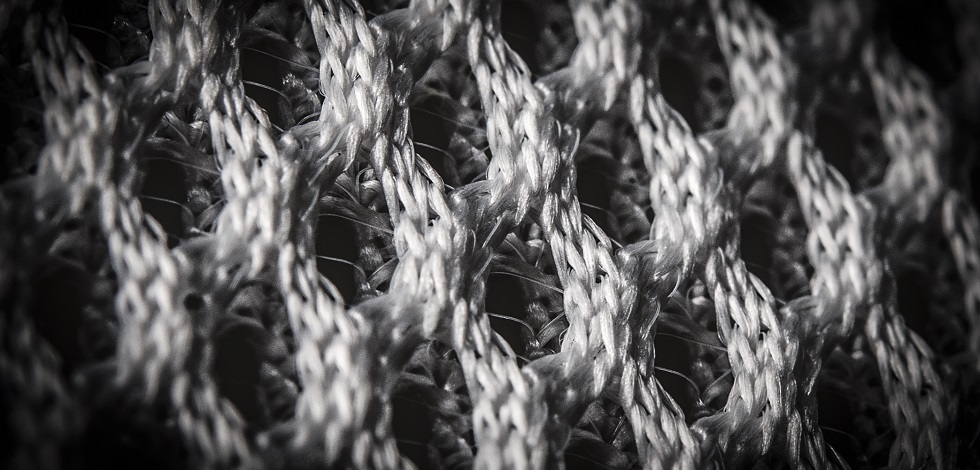

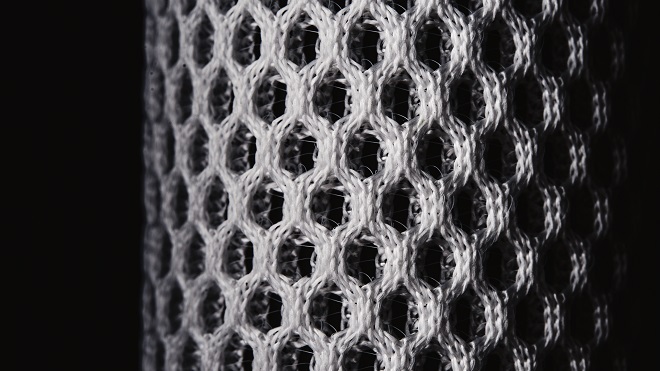

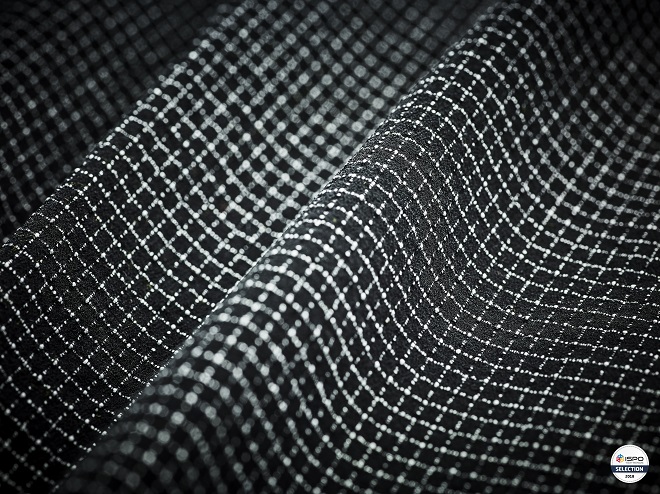

It depends. We are originally a materials company. DSM is the inventor of ultra high molecular weight polyethylene fibers, branded as Dyneema. We invented it over 40 years ago. A couple of years ago we decided to pursue this sports and lifestyle market. As we started learning about different market needs, we saw denim. Three to four years ago, there was a project with Levi’s. That was the first step of integrating into the denim market. You can still buy Levi’s with Dyneema in them. With that specific denim, we blend 4-7% of Dyneema into the cotton. It’s something completely different to Saint jeans with their super strong motorcycle denim, while Levi’s is aiming at improved abrasion resistance. With Dyneema in fabrics you can play with the kind of performance you’re looking for, and it won’t impact comfort. The concept plays on the axis of lightweight versus performance, strength, tear, cut, and abrasion resistance. That’s what we do.

“With Dyneema in fabrics you can play with the kind of performance you’re looking for, and it won’t impact comfort. The concept plays on the axis of lightweight versus performance, strength, tear, cut, and abrasion resistance.“

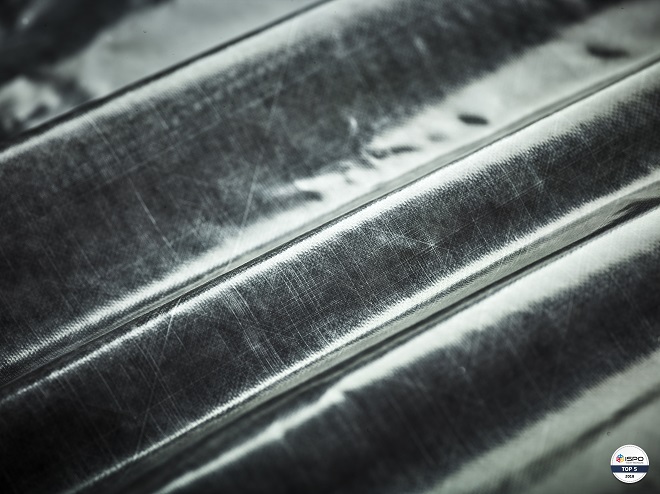

You mentioned Dyneema composite fabrics. In May 2015, we acquired Cubic Tech Corp. Cubic Tech is the inventor of this composite fabric, originally developed for sailing. It originated for the America’s Cup in 1992. These composite fabrics have a different look and feel than what you’re used to from a normal fabric.

A lot of what you’re working on is new projects and potentials. Where is most of the ultra high molecular weight polyethylene going right now? What industry or applications represent your existing market strength currently?

Dyneema is historically active in three markets: ballistics (bulletproof vests and vehicles), ropes and nets for large maritime operations, and cut-resistant gloves. These are our three major markets where we have been active for years. The market that I am developing is a new segment for performance fabrics.

“DSM is the inventor of ultra high molecular weight polyethylene fibers, branded as Dyneema. We invented it over 40 years ago.“

Are you working with brands in the bags and luggage space?

We have quite a few customers that are active in equipment. So you have companies like ZPacks, Hyperlite Mountain Gear, Mountain Laurel, Hammock, and CiloGear. Now we’re also seeing more brands outside typical outdoor markets, like Outlier for example. People like to experiment with our materials. It can be lightweight, it can be durable, it can be unbreakable. There was also a Tumi and Public School collaboration.

How do you think about competitive solutions for these high strength, high tear resistance, high abrasion fabrics? For instance, The North Face have recently talked about synthetic spider silks and trying to move that into outerwear. Are all the alternatives to Dyneema and ultra high molecular weight polyethylenes on your radar?

We don’t really talk about the competition. We focus on innovation. Dyneema is always pushing the limits of material science, seeing what’s out there and what the future may bring. I cannot share what we’re looking at specifically.

“Dyneema is historically active in three markets: ballistics (bulletproof vests and vehicles), ropes and nets for large maritime operations, and cut-resistant gloves.“

If you look at every market that we’re active in, we’ve developed a specific Dyneema fiber that is originally designed for that market. But of course there are also different applications in different markets. In our life protection market for instance, we have developed technology for maximum performance in a lighter solution. We’re always pushing the limits of possible innovation.

“If you look at every market that we’re active in, we’ve developed a specific Dyneema fiber that is originally designed for that market.“

When you think of a polyethylene, it’s quite slippery and hard to stick to.

Correct. That’s true for our fiber as well. All the usual suspects that are true for polyethylene are also true for our fiber. So we have technology to make it stick. We are capable of sticking different films to our fiber.

We’re doing a lot of work understanding how we can bond the fabrics together. We do a lot of these trials in-house. Currently available are cutting and sewing, taping and welding. We have a range of technologies in-house, but we’re always looking for partnerships in this field to scale up or help us with new technologies to make it better, more efficient, or more interesting for brands to work with us.

It feels like much of the development work you’re doing is in bringing new feelings, responses and performances to fabric by compositing it. It’s starting to feel more accessible to bag and luggage brands, as there’s more ways to integrate it. Is there a standard range of materials that carry brands can buy and sample and try using, versus the brands that really want to design something custom like the way Saint is doing with you?

We have both. We have a standard portfolio of fabric and we can customize. It’s not off the shelf, but we sell on a regular basis. Let’s put it that way. And then there is the capability to customize fabrics. We feel it would be an added value for brands to differentiate. And of course, we have a very broad network in the industry. We work with several players in the industry to customize fabrics in-house. So we have the capabilities for brands to make a fabric that suits their needs. That’s what we try to do on a daily basis.

“We have a standard portfolio of fabric and we can customize.“

What are you most excited about right now? Are there things that have just landed in the market or that you’re working on that you feel are really opening up the horizons for what’s possible?

A lot is still to come. I know some of the developments we are working on. For me it’s really exciting that we can change something in this market. My feeling is that we’ve just started. We’re at the beginning of a new innovation era here, both from a performance perspective and comfort perspective, but also from an economic perspective. I’m ready to move forward to the future of Dyneema.

“We work with several players in the industry to customize fabrics in-house. So we have the capabilities for brands to make a fabric that suits their needs.“

Excellent. Thank you so much for your time. We really appreciate it.

Thanks!

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews