Industry Insights :: Durable Water Repellents

It’s awesome when water beads, but some of the durable water repellents used with fabrics mess with the environment. So, what DWRs do you use? We rang in BLC Leather, a specialist boutique leather consulting and technology support company, to give us the low down on the different kinds of DWRs and the pros and cons involved in using them.

Warning: this is some serious industry geeking and for those savvy in jargon and terminology, so feel free to click back to the main menu if this isn’t your cup of tea…

–

What are DWRs?

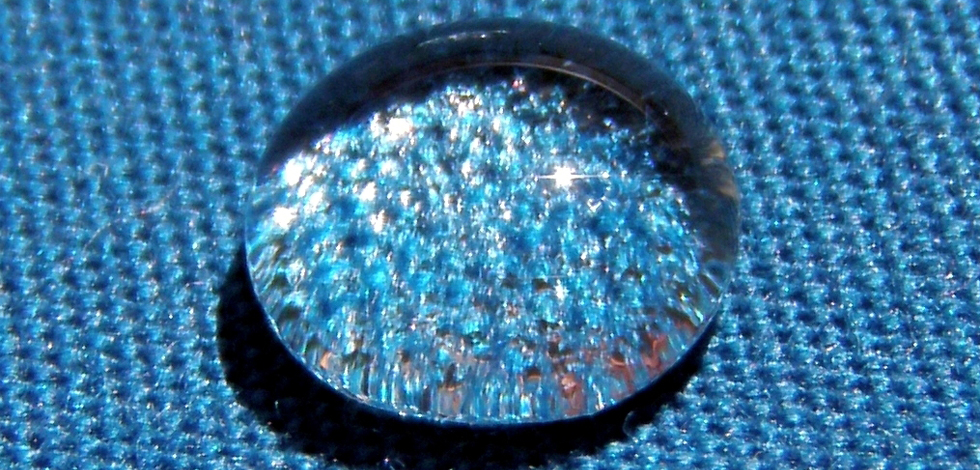

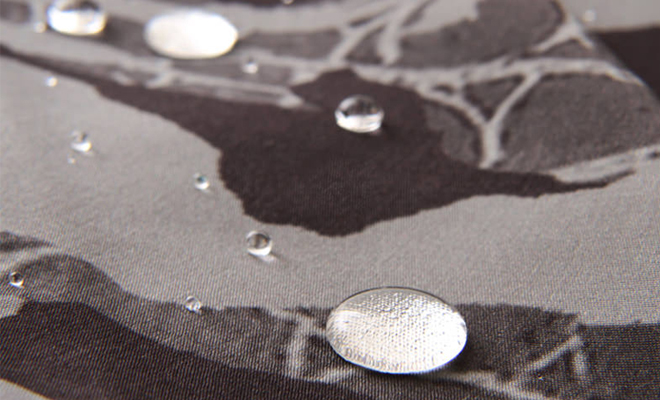

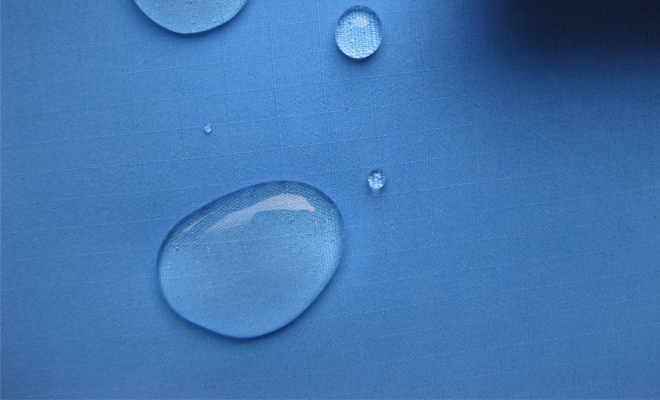

DWRs are topical finishes applied to fabrics to provide protection against water, oil and soil. DWR finishes add value to textile products. In addition to providing protection against water, oil and soil, these finishes also extend the life of products and keep them looking newer longer.

DWR technology has historically been achieved with textile finishes that contain a polymer to which long-chain perfluoroalkyl groups have been attached or non-fluorinated finishes. Long-chain fluorinated polymers often contain residual raw materials and trace levels of long-chain perfluoroalkyl acids (PFAAs) as impurities.

In 2011, the ZDHC brands made a commitment to set forth a timeline for the elimination of DWR technologies which may contain or degrade into long-chain PFAAs such as perfluorooctanoic acid (PFOA) and perfluorooctane sulfonate (PFOS). With the heightened NGO focus and pressure to move away from long chain chemistry, many have been looking to the shorter chain or non-fluorinated chemicals to provide the answer.

Alternative chemistries

Short-chain fluorinated repellent chemistries

In light of the concerns associated with long-chain PFAAs, there is a shift towards DWR chemistries with shorter perfluoroalkyl chains (also termed “C6” or C4” depending on the number of carbons in the perfluoroalkyl chain).

Short-chain fluorinated DWR chemistries are now promoted by the chemical industry as having comparable repellency and other performance attributes to long-chain chemistries. The industry is, in fact, on a learning curve to match the performance levels of DWR finishes with long-chain fluorinated chemistries.

Paraffin repellent chemistries

Paraffin was one of the earliest water repellent chemistries used. These repellent products are generally emulsions containing aluminum or zirconium salts of fatty acids, usually stearic acid. They provide good water repellency due to their zirconium ion holding onto fiber, and the fact that their water repellent groups have good orientation on fiber surfaces. They are generally compatible with other types of textile finishes but they have increased flammability. Despite providing good water repellency effects, paraffin repellents do not repel oil and are generally not durable to laundering and dry cleaning. Additionally, fabrics treated with paraffin-based finishes are less permeable by air and vapor, resulting in poor wear comfort. Paraffin repellent finishes can be applied by both padding and exhaustion finishing processes.

Silicone repellent chemistries

Silicon repellents offer a high degree of water repellency at relatively low concentrations. Yet, their repellency can be reduced if excess amounts are applied. They have only moderate durability to laundering and dry cleaning, and no oil and soil repellency. Waste water, particularly from residual baths of the finish application processes, is toxic to fish. However, some silicone repellents can be applied by exhaustion process.

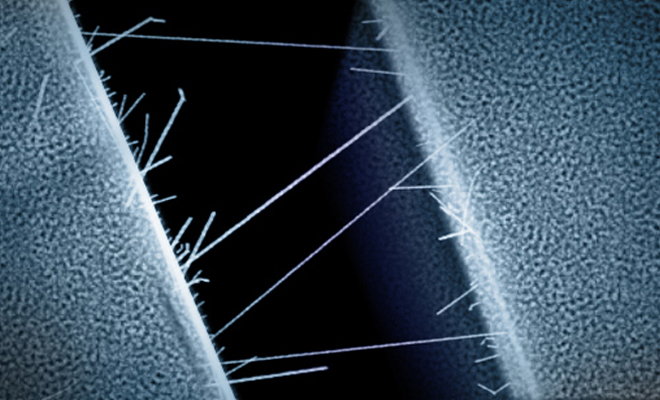

Nano-material based repellent chemistries

Repellent chemistries containing nano-materials are coated on fabrics to achieve desirable properties without a significant increase in weight, thickness or stiffness. The properties that can be imparted on textiles using nanotechnology include water repellency and soil resistance. The use of chemistries containing nano-materials to impart water repellency and stain resistance effects on textile is one of the most common ways nanotechnology is being used in the textile industry. To achieve these attributes, fabrics are embedded with tiny fibers, called nano-whiskers. Nano-whiskers form a cushion of air around fiber to repel water and stains. This treatment is believed to be durable to repeated home laundering cycles.

With respect to hazard, there is limited health and safety and environmental impact assessment available of nano-materials. Available evidence suggests that nano-materials have toxic properties to both human health and the environment and may have greater risk than larger particle. Unlike larger particles, nano-materials are capable of being transported within human cells and be taken up by cellular structures and cause cell damage due to their greater chemical reactivity.

Conclusions

Moving from long chain to short-chain fluorinated DWR chemistries is a complex process. There is considerable research in this area and whilst there tends to be performance concerns, alternative options do exist. It is critical that the short-chain fluorinated DWR chemistries supplied by chemical producers, including their raw materials and by-products, are evaluated for their human health and environmental impacts. This will ensure that potential substitutes are not associated with substances having comparable health and environmental impacts as long-chain fluorinated chemistries.

The move from fluorinated to non-fluorinated DWR chemistries is more challenging and one that also requires in-depth research to realise the practical application of non-fluorinated DWR finishes on textile products. Research and development efforts are also needed to make certain that non-fluorinated chemistries can provide the desired fabric attributes as well as meet their defined performance requirements. Significant efforts are currently ongoing in this area.

For more information on DWR chemistry please contact info@blcleathertech.com or call +44 (0)1604 679999.

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews