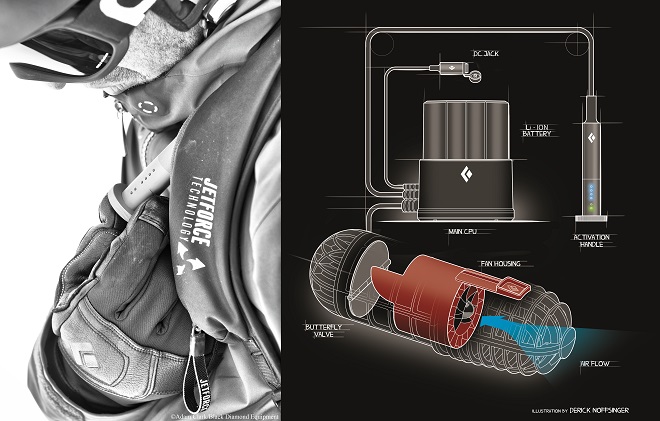

From Rough Diamond to Polished Design :: Black Diamond JetForce Interview (Part 2)

Fresh off part 1 of our interview with Black Diamond’s Pete Gompert, Derick Noffsinger, Nick Rueff and Jon Coppi, we’re sliding right into part 2 to learn more about their truly innovative JetForce series of avalanche airbag backpacks…

Andy: Have there been unexpected benefits that you guys didn’t think would be there with the fan system but you’ve ended up saying “Wow, that’s actually really important”?

Pete: I’d say the biggest one is probably the deflation. After three minutes this thing actually sucks all the air out. We actually buried Coppi and tried this…

Jon: We had a six-foot piece of plexiglass and I put the airbag on with an AvaLung so I could breathe under the snow. I’m behind this piece of plexiglass about 2 meters under snow pack and deploy the system. Then, I wait under the snow for the three-minute period, while breathing on an AvaLung and wait for the deployment cycle. And sure enough, at the end of the three minutes the balloon deflates and then I’ve got a 200-liter air pocket behind my head.

Pete: Not only could he breathe, he could move his arms enough to start digging and moving around which was cool. The way this all came about was that we were playing with the fan one day and we were like, “You know, there’s no reason we couldn’t run this backwards” so that just kind of happened halfway through and it turned out to be a really good thing.

Jon: It’s a fully programmable system so in the future we can make it do pretty much anything we want, obviously within reason.

Nick: And then of course the other really big benefit is the ability to deal with punctures or tears…

Andy: That it continues to force air in?

Nick: Right, exactly. And then not only that, three minutes is far longer than a typical avalanche lasts but you can also envision scenarios where when you’re initially trapped in the avalanche having the pack being impinged in some way. And for a compressed gas system, if there’s any of that impingement at the onset then you may not get complete fill, you may not really get what you want out of that initial inflation. With ours, even if something is interfering with the system at the initial inflation, because you continue to get inflation throughout the cycle it just keeps working for you the entire time. And you can start to envision a number of scenarios where that would be particularly useful.

Andy: Is there an abort switch? You start inflation, you can kill it quick? With so many of these things when you hear about where issues have happened with existing airbag tech, people were like “Oh I didn’t think it was going to be a big slide, I didn’t want to deploy and waste my canister”…

Nick: Our system in that regard has a bunch of benefits. One, it’s an electrical-based system so when you arm it, it gives you visible and audible indication that you’ve armed the system. So it runs the fan in reverse which gives you an audible signal that the system is armed. Visibly you get a pulsing green light, so you now have visible feedback that the system is armed and everything is functioning correctly. With most all of the compressed gas systems, because they are only mechanical, you don’t get quite as much feedback that everything is working correctly.

“…it’s an electrical-based system so when you arm it, it gives you visible and audible indication that you’ve armed the system.”

Pete: Really the only way to know is to pull the cord…

Andy: But it’s so interesting even just in general backcountry etiquette vibe, there’s always the tradition of test the beacon before you go, you check each other…

Derick: This is by far one of the biggest benefits to our system. The ability to practice, over and over.

Jon: Just practicing with it is huge because when heading into the backcountry it’s super important to have confidence in your system. You’re skiing along, you set off slide and you feel the snow move, pull the trigger. It takes a minute and a half to repack the system after you’re done. If you feel spooked, pull it again. You’ll still have a few deployments left, it’s not that big of a deal. Whereas with a canister system you’re second-guessing yourself, “I don’t want to waste my one shot now”…

“It takes a minute and a half to repack the system after you’re done. If you feel spooked, pull it again. You’ll still have a few deployments left, it’s not that big of a deal. Whereas with a canister system you’re second-guessing yourself…”

Derick: Say you’re on a three-day hut to hut trip through the backcountry with a canister system; waste it on the first day and you’re not so confident for the rest of the trip.

Nick: The way that the system functions, when you first pull that trigger there’s about ten seconds where there’s nothing you can do. It’s sort of a safety-critical portion of that cycle where it will run the fan and it will inflate the bag. But after those first ten seconds you have the option of stopping the cycle. So, if it is a false alarm you don’t have to worry about using three minutes’ worth of battery power, you can stop it. But we wanted to make sure that when you pull that trigger the system is programmed that in those first ten seconds it does everything that it can to spin that fan and inflate the bag.

Pete: We run it for ten seconds which is actually three times as long as it needs to blow up the bag, which is another advantage over a canister. Just in that first safety window we already have three-time redundancy to fill the bag.

Andy: In the actual inflation, what sort of issues are you looking after there? In cars they have to say if you’ve got kids under six or eight don’t put them in the front seat. Is there a lot of thought about the way it inflates, making sure it doesn’t jam against your neck or doing things that might catch you out?

Derick: I think it’s the opposite; just make sure there’s nothing in the way that could ever NOT let it inflate.

Nick: There’s also a fundamental difference between avalanche airbags and car airbags. Car airbags, the primary purpose is to protect against impact…

Andy: And they have to inflate in the opposite direction to the way they have to cushion and so the inflation has to be even faster because you’re working against –

Pete: It’s like 10 milliseconds in a car, so we have an eternity compared to that.

Nick: So while an avalanche airbag may offer some protection from impact, that’s not the primary reason. The primary reason is to increase your overall volume so that you float to the surface in a slide. While there are some similarities in the way they function, the reasons are pretty different. When designing the pack and studying how the airbag comes out, we focused on how to deploy the bag in the most unobstructed way so that your volume can increase.

“So while an avalanche airbag may offer some protection from impact, that’s not the primary reason. The primary reason is to increase your overall volume so that you float to the surface.”

Pete: There was a lot of thought into the shape of the airbag too. Like you said, we didn’t want it to push your head forward. We made a really conscious decision to keep it all back so you could still ski and see. Stuff like that was really important. Also, we made ours bigger because the bigger object rises to the top in slides. And then also we liked the idea of having a balloon location at your shoulders and above your head because that means you’re probably going to end up right side up when the snow stops moving, whereas if it’s lower down who knows where you’re going to be.

Nick: And that’s actually been adopted into the standard. There are some requirements as to how and where that balloon is positioned relative to your body. It’s obviously not a good thing if at the end of a slide your body comes to rest upside down, which is why you’re not going to see an airbag where it comes out at your ankles. So every company approaches that a little differently but the intention is always the same. You want the body to float to the surface and as best you can, you want the head to be protected and as high as possible, hopefully above the snow.

Andy: There’s a lot of unique hardware on this pack, isn’t there?

Nick: There is, and there’s a very specific requirement for certification where it has to withstand a certain amount of force and the balloon being removed from the bag and bag being removed from the body. So in terms of the way this pack is constructed, it’s constructed more like a climbing harness or something like that than a normal pack. All the main points are pretty significantly reinforced so that it can withstand that required load.

Andy: It’s so interesting, it’s such a massive project but BD is in such a unique space with PIEPS, with BD climbing, with backpacks, harnesses…you can see why no one else has managed to get this out in the same time.

Derick: Agreed, we sit at a unique crossroads between design and engineering at BD. A perfect example of this was when we designed the metal waist-belt buckle for these packs. I had drawings out to Pete in the morning and we literally had prototypes made downstairs by the end of the day, ready to throw on our Instron Machine. We were able to fail quickly to make sure we could find out exactly where we wanted to be. Being able to build functional prototypes and test them in-house is so helpful to the design process, especially when you build life-saving products. The metal buckle also passes through the crotch strap that dives between the user’s legs to help keep the pack attached to the user during avalanches. We made the crotch strap bright red so when a mountain guide is out with a bunch of guys that are using these packs, they can visually look down the row and make sure everybody has their crotch strap on.

Pete: That is a very important part of the system. I know a lot of guys don’t wear those but there’s a real chance that your pack is going to get torn straight off your back and you’re going to be buried underneath the airbag. So, wearing that crotch strap is super important.

Andy: They’ve found people with their ski pants pulled off and everything by the slides.

Nick: I think there’s actually been a couple of reported cases where people have been strangled with the sternum strap because they weren’t wearing the crotch strap.

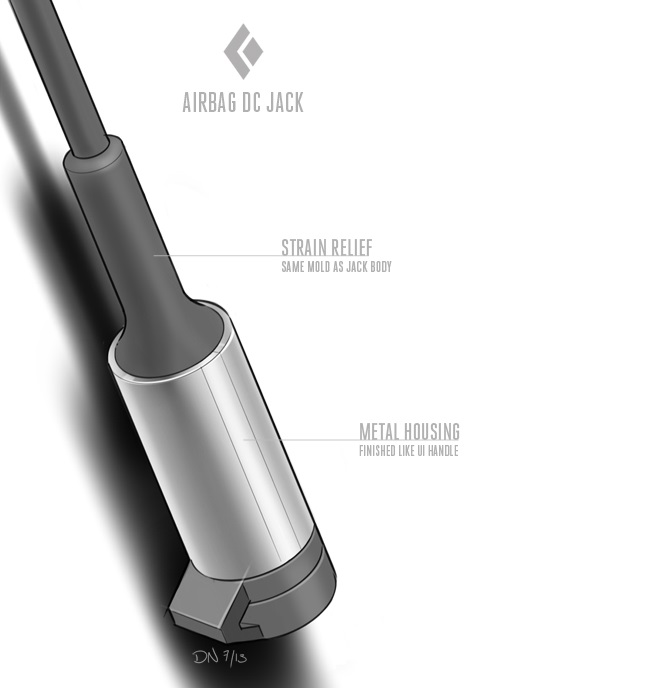

Derick: All of us here will always wear the crotch strap, probably because we are so close to this project and the statistics that come with it. Another great safety feature with the JetForce system is the ability to “check your status”. It was really important for us to make sure, from a user interface point of view, that you can check your status all the time just by looking down at the deployment handle. There’s a green pulsing light that you see on the handle if the system is ready to go and a red light if it’s not.

“…it was really important for us to make sure, from a user interface point of view, that you can check your status all the time just by looking down at the deployment handle.”

Pete: The red light comes on for low battery and also if there’s something wrong in the system diagnostic. So before you get on that helicopter, if it’s red – we hope it’s not – you know your pack isn’t ready to deploy. It’s just another level of safety.

Derick: Also, to check battery status you can tap on the bottom of the handle and blue LEDs will light up indicating how much power you have left.

Andy: Can you buy a spare battery and take that out with you?

Nick: Right now we don’t have spare batteries available for sale. That is the plan. The battery is user-replaceable but it is not really designed to be removed from the system on a regular basis. Rather than the cordless drill approach where you take the battery off and put it into a charging station, we designed the pack so there’s a power supply charger that you plug into the wall. You plug it into that DC jack and you’re able to charge the system without ever having to remove the battery. A spare battery will be available but there isn’t one available currently. But it’s easy to charge and it’s pretty user-friendly in terms of having to charge it on a regular basis.

Pete: The goal was to make it as easy as your cellphone to keep charged. You don’t take the battery out, you just plug the whole thing in at night and it’s ready to go in the morning.

Derick: To inflate the balloon you just pull down on the handle.

Andy: How long is charging time on the battery if it’s been fully depleted?

Nick: If it’s been fully depleted you’re probably looking in the neighborhood of four to six hours, or overnight…

Pete: The longest avalanche we could find was less than a minute so we figured we’d run the initial inflation for a minute. If you’re still in an avalanche at this point, we probably can’t save you. The standard requires us to stay inflated for three minutes so the system will continue to keep the bag inflated.

Derick: So it’s keeping it topped off.

Andy: And at any point you can stop that?

Derick: Yeah, you can.

Andy: The psychology of being more willing to deploy feels like such a massive part of this…

Nick: And practicing also, learning how to quickly deploy it, learning how to repack the system…

Jon: Even just getting a feel for how hard you have to pull.

Pete: I would bet the percentage of people who have actually deployed their airbag pack is pretty low just because it’s such a hassle.

Andy: So in the deployment of the airbag it’s broken through a zip that you guys have custom designed for that…

Pete: So basically the way it works, there’s small metal pins that you clip the airbag balloon opening flap to. Then when you pull the handle, it triggers the fan and also pulls pins out that allow the flap to open. As soon as the fan starts running the pressure of the balloon rips the zipper open and the balloon comes out.

Derick: We wanted to make sure this solution wasn’t something that would degrade over time like Velcro, especially in snow.

Nick: So it’s pretty easy but it is important to note that to reset the system you have to move the bars back and you have to make sure that the zipper pull goes off the end of that zipper.

Pete: If you do forget to do that, we have enough power to break that zipper. Your bag will still deploy but it’s not good for it, so it’s important to slide that zipper past.

Nick: But it’s quick and easy to do so you can repack the system and be ready to go again in a couple of minutes.

Pete: Another thing we didn’t like with all the other systems was that you had to fold the bag in a certain way, like folding a parachute, to repack the balloon. That didn’t really appeal to us so we designed this thing so you just stuff it in, there’s no thinking about it and it’s really easy.

Jon: After you’ve practiced with it, you can get it down to around a minute to repack the system, if not less.

“After you’ve practiced with it, you can get it down to around a minute to repack the system, if not less.”

Derick: About the zippers specifically, every company uses a plastic-toothed zipper, basically a Vislon zipper with a burst zone. You’ll see with a lot of those packs that if you leave the zipper foot on the end of the zipper the power of the balloon deploying will break off the last couple plastic teeth on the zipper and those packs are basically unusable at that point. We wanted to come up with a solution to this and we went with a coil zipper over a plastic tooth zip. What’s great about this is it can “run” if it’s peeled open, unlike a plastic tooth zipper. So when the flap opens there’s virtually nothing that can keep the zip from peeling. And the zip is coated with a waterproof coating to keep from freezing –

Pete: It’s got a DWR type coating on it.

Derick: …and so even when it’s frozen at -30 degrees Celsius the zipper teeth don’t get stuck together and they just run open.

Andy: To us at least it feels like this is an absolute game-changer. It just feels like it’s what the industry needs. What are you envisioning with other brands as they try and replicate this? Are you scared that they may botch the job, it’s pretty hard and they may tarnish the idea of fan-forced airbags or are you guys being fairly open with this information?

Nick: We have applied for a couple of patents and so there are aspects of this system that are protected. We certainly believe that this is the next generation of airbag technology and there’s no doubt that others will be following suit. I think the way the standard is written right now provides – there are some good solid requirements in that standard that will sort of force people if they want their product to be CE certified to build a robust system.

Andy: So for you guys, you would endorse and suggest that is the standard that if anyone is going to be buying a pack like – I’m guessing it will take brands a few years to sort of replicate – but if they’re going to be buying a pack like this, that’s going to be the best standard.

Nick: Yeah, and all the major industry players have been a part of creating that standard so everyone knows about it and everyone’s been a part of it. So yeah, that is sort of the comprehensive industry standard for avalanche airbags.

Pete: And it’s a tough one to pass, like you were saying, it’s a pretty high barrier to enter into this because there’s so many little engineering challenges.

Derick: We believe competition is always good, it always moves the needle forward. I think this is one of those products that will be super hard to replicate, let alone improve upon.

Andy: Can you imagine licensing this out to other brands to be able to put ski bag modules onto this in the same way that ABS has?

Nick: How that is executed on needs some discussion. The main challenge with our system is that the electronics, the backpack, the entire system is very tightly integrated, so it doesn’t really lend itself to that module. But licensing is for sure a possibility. We are still in the early phases of this project so it’s hard to know what the timeframe for that is, but yeah absolutely it’s a possibility.

Derick: I believe one super exciting aspect to speak to about this project is that airbags have been around for almost thirty years now. The technology in those thirty years has gotten to a point where it’s really slowed down quite a bit. This is our first year launching this and we have plans in the works, that we can’t discuss of course, that will dramatically push this technology forward. This is all because so many different industries are working with this type of technology and battery technology in general, it’s getting lighter by the month. There’s so much investment from all different industries being thrown into battery technology. And on the flip side of the coin I think I can count on one hand how many industries are pushing canister technology forward. And then there are physics in general that are keeping the canister industry from pushing forward – you can only squeeze air so much. So it’s a really cool place to be in that sense. We are right at the tip of something that is just going to get lighter and faster.

Pete: Exactly, that’s one of the huge benefits of being battery-based, we have these giant corporations working on battery technology for us and that actually works in our favor as we want to get this thing lighter. All that research can be used in this pack.

“That’s one of the huge benefits of being battery-based, we have these giant corporations working on battery technology for us and that actually works in our favor as we want to get this thing lighter. All that research can be used in this pack.”

Andy: For projects like this you have to start locking down variables from fairly early on in the project. Has there been anything that you kind of locked down and committed to it, either this fan size or this battery size or something where by this end now at release you’re like “Oh bugger, maybe we got that a bit wrong…”?

Pete: We’ve designed a lot of stuff. There’s always a list at the end of any project that’s the “Wish we could have done” list, we’ll save it for next time. We have one of those. Probably not going to discuss it but there’s definitely a list of things we can improve.

Andy: But that just means the next few years should see a great continuous update. But the good thing about this stuff is it’s potentially life-saving so a lot of people should be willing to say “Am I going to be tight about this or am I going to – if I’m halfway down that slide and it’s building up on me, am I going to feel really silly for not spending this money?” So hopefully there’s a good update. But as you said, it’s very integrated so at the moment if someone wants – if they do some overnight touring and some resort sidecountry, that means buying two packs at the moment and there’s no real synergy between that.

Derick: I think it’s highly possible – and we kind of experienced this with the bags for POC and PIEPS – this isn’t really a licensing thing because they’re part of Black Diamond but we were able to, in the middle of the process, make these packs for them that got to the capacity they wanted and looked the way they wanted. So without changing the bag too much it was super easy and I think in further generations of this thing we’re going to try to make sure to keep in mind modularity and licensing.

Pete: We had consciously took that off the table pretty early because we wanted to make really good ski packs and we had enough on our plate getting the system working that we didn’t feel like we could make it super modular and also the best ski pack we’d ever had at the same time. So we definitely went the route of making a better pack.

Andy: I think that’s excellent. It makes great sense. So in terms of carry comfort, a day of skinning up, have you found the system is fine? There’s no major compromise with it?

Jon: I’m pretty blown away by how well the bags carry. You pick up the bag, you can tell there’s stuff going on there for sure from a weight standpoint but as soon as you throw it on, it’s like you forget about it after a little while going uphill. It carries really, really nicely, especially the bigger packs. You’ve got the whole SwingArm technology where the harness system moves with you as you’re moving and that’s really helpful, the core of the weight is lower. Just building on what we’ve been doing the last few years with our ski packs.

“You’ve got the whole SwingArm technology where the harness system moves with you as you’re moving and that’s really helpful, the core of the weight is lower.”

Derick: The SwingArm technology is a simple idea. There’s a bike cable in a bike cable housing that runs down by the mating seam giving the shoulder straps 1.5 inches to 2 inches of swing, or movement. It makes skinning totally different. Even when you have the bag packed totally full your shoulders are able to rise when you need, so it moves with you.

Andy: And it’s a system like Aarn Design in New Zealand and a couple of others have played with variants on this and for anyone who hasn’t actually put one on it’s a radical difference. You don’t get that strap rising off your shoulder as you tilt. You get this sort of slight delay of the bag moving that just cushions everything.

Pete: I think that’s really important for skiing too just because you’re always squaring your shoulders up to the fall line, so you’re pretty much spending your whole day twisting one way or the other and that SwingArm technology makes a huge difference.

Andy: And then water resistance performance, things like that, how do you decide what to bother doing there?

Derick: We’ve made sure the exterior material of the pack is silicone-coated to resist water. It’s a lightweight ripstop and it has a pretty high abrasion resistance. The silicone coating also allows the fabric to move out of the way quickly and not become stiff at very low temperatures.

Andy: Well it’s an incredible project. For me it feels like it’s really the future of airbag backpacks at least for the next five years. It’s a huge achievement and I’m really excited to start seeing them out there.

Nick: Yeah, we sold out online in about 24 hours.

Jon: Yeah, everybody’s texting like “Hey, I’m trying to get a JetForce, what retailer has them? When are you going to put them back on your website?”

Andy: But intentionally limiting production for the first year to something manageable, you make sure it’s all going killer…

Nick: Yeah, we’ll be ramping up production for F15 for next season, and we’ll continue to do so to try to provide the quantities that people are looking for. But that is the challenge, but we’ve brought it to market at this point so it’s just a matter of optimizing the supply chain and getting things dialed.

Andy: And then expecting PIEPS and POC versions next season or…?

Nick: No, they’re already out. This season was a mix of Black Diamond, PIEPS and POC product.

Andy: Do any of you have a favorite amongst all that stable?

Pete: I like the Halo 28. It’s your everyday great ski pack. And it says BD on it…

Andy: A bit of pride…so good. Well thanks so much!

Pete: Yeah, thank you.

Derick: Thank you.

–

See the interview (and the pack in action) below. Word of warning: this vid’s not really nailing a pro standard, sorry! But if you’re a diehard fan or carry geek, you might just dig it.

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews