Carry Innovation :: Interview with Vertepac

“Stan went out to get a joint,” was the first thing co-founder Jeroen Janssen (right) said when I entered the Vertepac office in Vinkeveen. Now, being in the Netherlands, that wasn’t a terribly strange thing to say and I interpreted it in the way most Dutch guys would. A bit awkward for an introductory remark, but hey, who am I to judge! Stan (Stanley Sie, Vertepac’s other co-founder) entered soon after and it turned out a “joint” was one of the components of Vertepac’s unique carrying system.

What followed was a three-hour long bustling interview with two guys who are beyond driven to create a highly innovative backpack enabling freedom of movement and carry comfort!

How did you get started in this?

Jeroen: We’ve both worked for a large number of national and international clients in the field of design and production. I run a design agency for mainly functional products made out of textile, we do a lot of work for the automotive industry. Stan is a freelance product designer with a scientific background and a lot of experience in visualizing. Like anyone in any creative business, we daydreamed about creating something meaningful with complete freedom and without having to worry about client politics. About developing a high-quality and durable product that actually stays true to its initial concept. With the Vertepac, we have been able to do just that.

Where did the idea for the Vertepac come from?

Jeroen: It was a “flash of inspiration”. I travel a lot for my work and I was always annoyed, seeing all these people walking around with horrible bags: they may be fashionable, but not functional. As humans, we went to the moon and back, but backpacks are still bags with shoulder straps. Then there’s this particular night, when I’m in an airport in China, and I’m thinking: carry products should support how we move our bodies. I’m starting to draw and draw in the plane and I’m starting to realize I’m drawing a form that’s similar to the human body. I poked my colleague from his sleep and said: Look at this! I came home and started to prototype three days later. That was only the first idea though; I worked with Stanley before and asked him to join me soon afterward to develop all the ideas I had into a real product.

Stanley: Jeroen showed me a few prototypes, and although there were a lot of improvements to be made, the basic concept really struck some chords. When we started out, we thought we’d finish it in a year [laughs]. Four years, many prototypes and even more long nights later, it’s ready to be shared with the world.

What’s the vision behind the product?

Stanley: Foremost it’s freedom of movement and carrying comfort. When you’re hiking, climbing, skiing you’re constantly moving and whatever you’re carrying should not get in the way. Most backpacks provide some form of rigidity which limits your freedom of movement. Depending on what you’re doing that can be anywhere between annoying and dangerous. Next: Whatever weight you’re carrying should be on your hips instead of your shoulders, so it bypasses your upper body. The load no longer will be on your spine, the shoulder straps will not hinder your blood flow, and the upper body is able to move freely. The Vertepac frame has a spine form (EPS™: extendable parallel spine) that works similar to the human spine; it provides structure yet it offers flexibility.

Jeroen: Further, when you’re doing any intense activities, you’re going to sweat. The best way to solve this is to have as little as possible contact points between your body and your carry. That’s another thing the spine supports. At the same time, it protects your back.

Finally, as you can adjust the Vertepac frame to your upper body height, we thought the frame should enable carrying multiple bags, so in our prototype phase we started developing a hiking pack, daypack, waterproof pack and travel pack that can all be attached to the frame.

How did the product evolve?

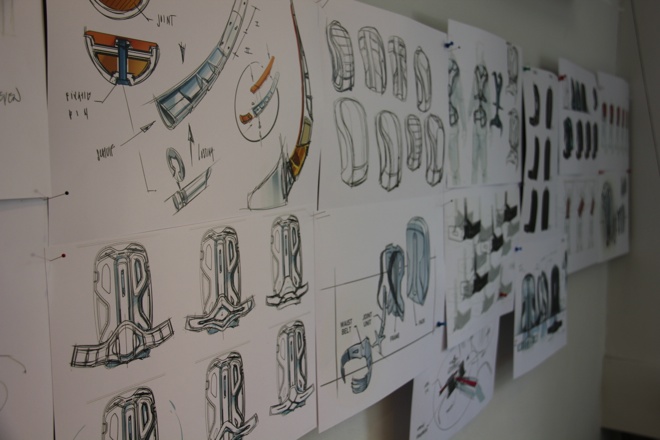

Jeroen: Basically we prototyped and prototyped and prototyped. We tried various materials to gain more knowledge about the rigidity the product required. We tried various forms to gain more knowledge of the best way to support the spine. One epiphany was when we discovered the spine form we had used up until then should be inverted…because it did exactly the opposite of what we were trying to accomplish… That was painful…

Can you tell us a bit more about the prototyping phases?

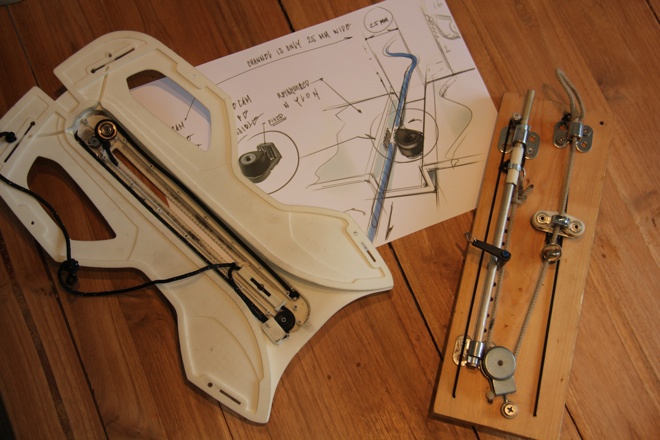

Stanley: Sure, we went through roughly four phases. We started out by prototyping with epoxy/glass fiber, molding rubber forms with existing backpacks to test the design principles of what we were looking for. That convinced us we could actually make a viable product out of this.

Next we did a lot of SLS prototyping/3D printing to see how we could make the spine adjustable, so we could cater to people of various heights, and retractable for practical purposes (i.e. putting the bag on the ground).

We came on to the idea of modular bags because the frame in itself supported most of the weight distribution and freedom of movement. To us it was a waste to use the frame just for one bag, so we decided to develop several and design the way the bags are attached to the frame.

To get the spine form right, we must have tested at least 20 different versions. Next to the weight and movement support we had to take into account that the spine had to be “foolproof”; it shouldn’t break when you use it in an odd way.

So third; when the design was more or less ready, we milled the various components out of Polyamide block. This was mainly to test the design and components on rigidity and robustness and get a realistic view of the material used.

Finally, to get more test samples, we had vacuum castings made with a resin that approaches the characteristics of Polyamide.

(This is about the time Mr Zing needed a little break…)

There’s a pile of junk over there that has cost us a lot of money [laughs]. It’s basically useless now but it helped us to understand various forms and materials and how they would work.

Stanley: We’re testing a lot too; we went to a nearby army base and had soldiers run an obstacle course with the Vertepac. We’re testing how the frame copes with dirt or sand. We took the Vertepac on skiing and hiking vacations. We’re going to do an activity test with oxygen measurement to see if we can scientifically measure the effect of better carrying. And of course we’re gonna let Carryology review it!

How do you see the Vertepac within the carry/outdoor scene?

Jeroen: A big part of the outdoor and carry scene is focused on lightweight and fashion. Carry products are getting better and better; you can clearly see they’re being fine-tuned. But it’s still details, and although consumers really appreciate it, there’s no significant innovation.

Stanley: There’s a lot of focus on lightweight, sometimes at the cost of functionality. And you know, everybody can figure out that carrying 10 kgs less massively improves your carrying comfort. But at some point another few grams doesn’t matter all that much anymore. When you want to achieve breakthrough innovation, you need to look somewhere else than lightweight at this moment. With Vertepac, we’re adressing the core issues of carrying: freedom of movement and carrying comfort.

Jeroen: So we see weight as a part of the product, not as the main focus. The Vertepac frame weighs more than a few shoulder straps, but if you try the system, you’ll see what it’s really about.

What are the next steps for Vertepac?

Jeroen: A lot of things actually. We patented the spine concept and parts of the system. We’re supported by an incubator program by Delft University of Technology called YES!Delft and they help us out with legal stuff. Cordura® helped us out by providing the materials.

Stanley: We just launched at the Outdoor Show in July in Friedrichshafen (Germany) and got a lot of contacts there. We’re talking with some major brands right now. We’re looking for partnerships to further develop the frame and its applications in various industries (outdoor, sports, defense, professional climbing).

We’re also continuing working on our own bags and who knows, we might start a Kickstarter campaign!

We’re also continuing working on our own bags and who knows, we might start a Kickstarter campaign!

Jeroen: Basically, we were so deeply involved in the product design and development; we need to take a step back to see how far we’ve come and focus on the business side.

So far we’re self-funded, the Vertepac is production-ready and the next step will be to start production, either through partnerships or by ourselves. VC funding could be interesting but it’s just not that available in the Netherlands for these kinds of products.

And then we’ve got a whole lot of other ideas, but we’re not telling!

If you are interested in the Vertepac and want to stay updated go here:

Finally, what inspires you in the carry scene?

Jeroen: I’m generally inspired by brands like NeilPryde, Apple, Audi, Cabrinha. All kinds of developments in water sports, because the materials have just become so high tech in that scene. I can be amazed by sculptures.

Stanley: For me inspiring brands would be Festool, Apple, Porsche, Dyson, Nike, NeilPryde. I get a lot of inspiration from organic structures, street art, concept art, and a bit of Calvin and Hobbes along the way. 😉 And of course the mandatory amount of design blogs like designboom, Core77 and such.

Editor’s note: photos provided by Vertepac.

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews