Carry 101

In the relentless push for better outdoor gear, the quest for lighter, stronger, and more sustainable materials never lets up. We’ve seen our share of breakthroughs over the years at Carryology. But ALUULA—a Canadian-born material innovation—may just be one of the most significant yet.

From the west coast of Canada, where environmental awareness runs deep, ALUULA set out to create the world’s lightest, strongest, and most durable fabric—while ensuring it’s 100% recycle-ready. It’s a story of passion, science, and a willingness to rethink the very structure of high-performance textiles.

The Moment the Wind Changed

In 2017, Richard Myerscough, founder of both ALUULA and wind sports brand Ocean Rodeo, noticed something troubling: the materials used in kites—Dacron, polyester canopy fabrics—hadn’t evolved in years.

“We knew we could do better,” Myerscough recalls.

He brought in PhD chemist Pete Berrang to help invent something radically lighter and stronger. Windsports Design Lead Ross Harrington came aboard to push it through punishing real-world testing. Harrington also gave the material its name—ALUULA, Latin for “winglet,” represented by the brand’s feather logo. Later, synthetic polymer chemist Tyler Cuthbert joined as Chief Scientific Officer to further refine the material and reduce its environmental impact.

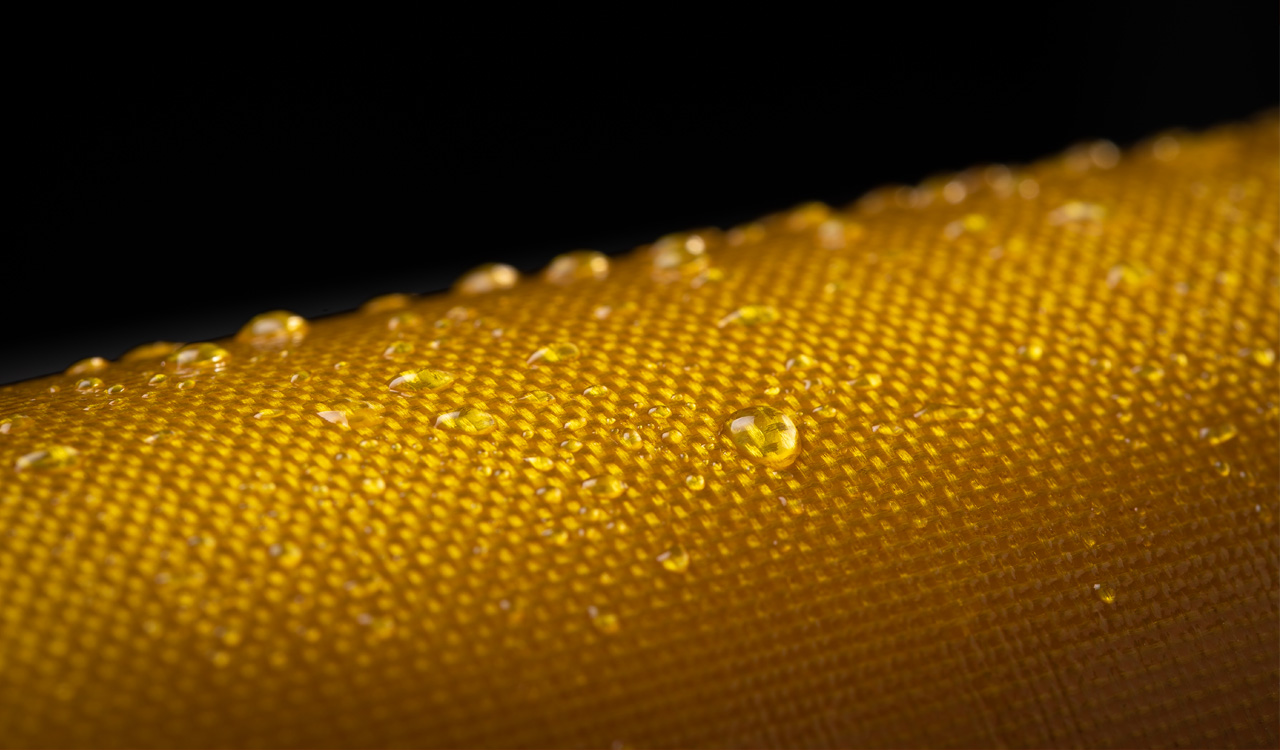

By 2019, ALUULA’s “gold fabric” hit the market. Kites became half the weight and twice as stiff, making them easier to launch in lighter winds and more stable in gusty conditions. The performance leap created an entirely new category of premium wind sports equipment.

Why Fusion is the Key

Most other high-performance laminated fabrics are like a layered cake held together with sticky icing (glue): You start with a strong base layer, then add a waterproof film, maybe another protective layer, and then glue all these different pieces together. This creates a strong material, but its weakest link can be the glue. Over time, or with a lot of bending and rubbing, that “icing” can get tired and start to crack or peel, causing the layers to separate. When that happens, your strong “cake” can lose its integrity, making it easier to tear or wear out. Additionally, because it’s a mix of different materials and adhesives, it’s very difficult to separate and recycle each part when the product reaches the end of its life, much like trying to un-bake a cake to retrieve all the original ingredients.

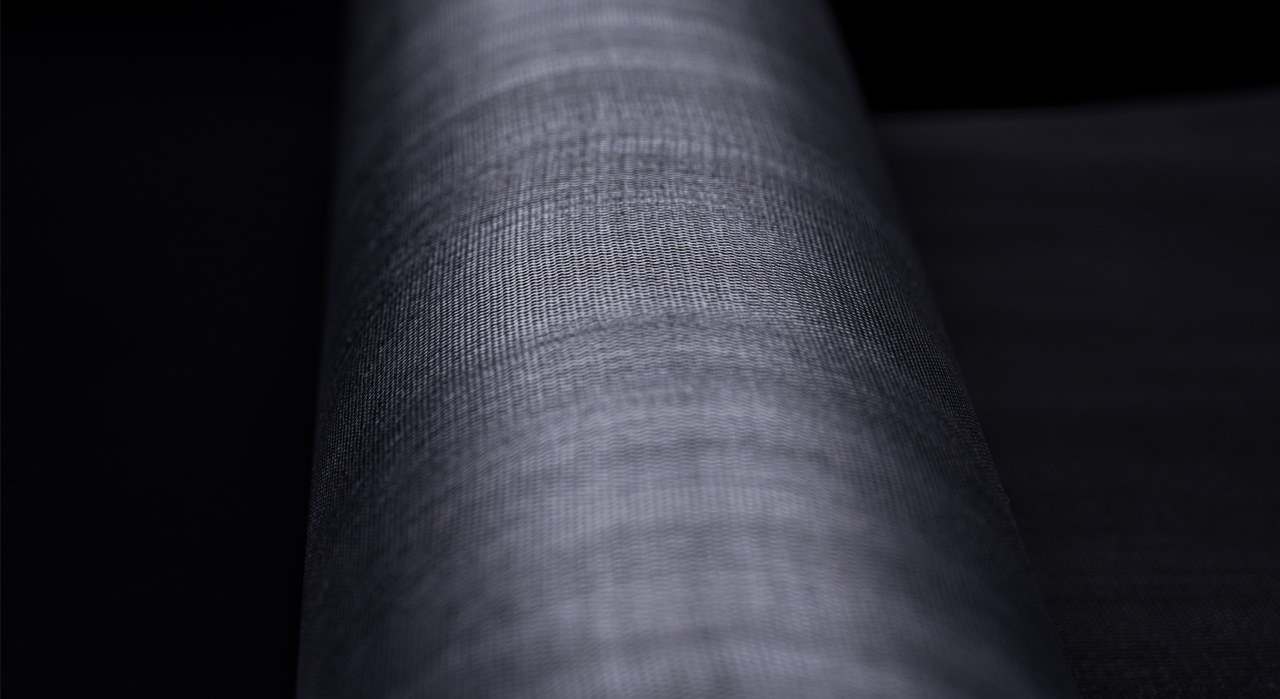

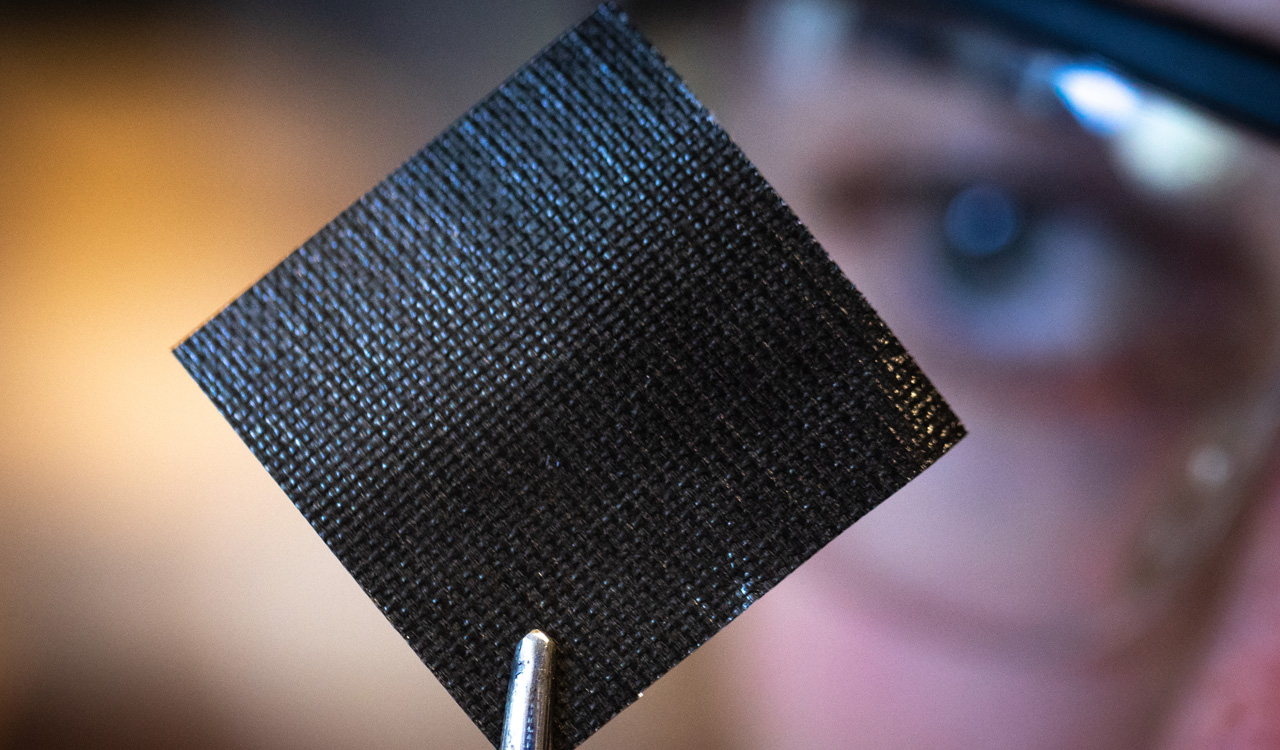

ALUULA fabrics, on the other hand, are like a single, solid super-block of the strongest possible material. Instead of gluing different layers, ALUULA engineers take tiny, incredibly strong fibers, all made of the exact same special material (UHMWPE), and fuse them together at a molecular level. It’s not a glue; it’s a unification, turning separate fibers into one new, unified substance.

This results in a mono-material that is naturally lighter, stronger, and inherently recycle-ready. This fusion also eliminates the risk of delamination or fraying, which can happen over time with traditionally bonded fabrics. Everything is simplified, from manufacturing to design, and crucially, future recycling processes. The strength of its key component, UHMWPE, is astounding, as most of our readers know. This allows designers, depending on the application, to drastically reduce the weight of the end product without the compromise of older, traditional lightweight woven nylons and polyesters.

This fusion tech also unlocks a wide range of design and manufacturing possibilities; ALUULA fabrics can be easily sewn, heat welded, and bonded to themselves. This means product designers can implement no-sew and glue-free construction techniques, leading to cleaner, more durable products. And for you, the adventurer, it means the possibility of stronger, more permanent field repairs with simple heat-activated patches, keeping your gear in action longer.

Three Fabrics. One Core Technology.

ALUULA’s lineup targets specific needs—but every product shares the same fused-fiber DNA.

Aeris™ – The featherweight champion. Highest strength-to-weight ratio, lighter than nylon or polyester, tear-resistant, and thermoformable. Weights range from 24 gsm to 98 gsm.

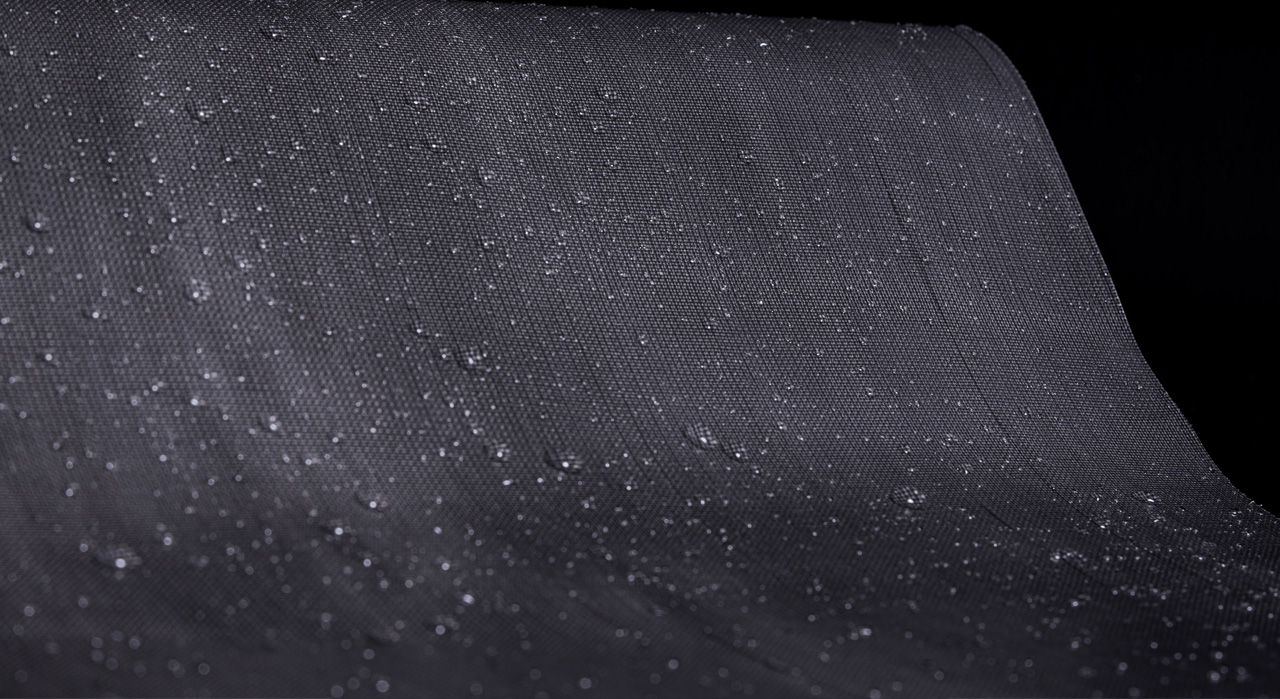

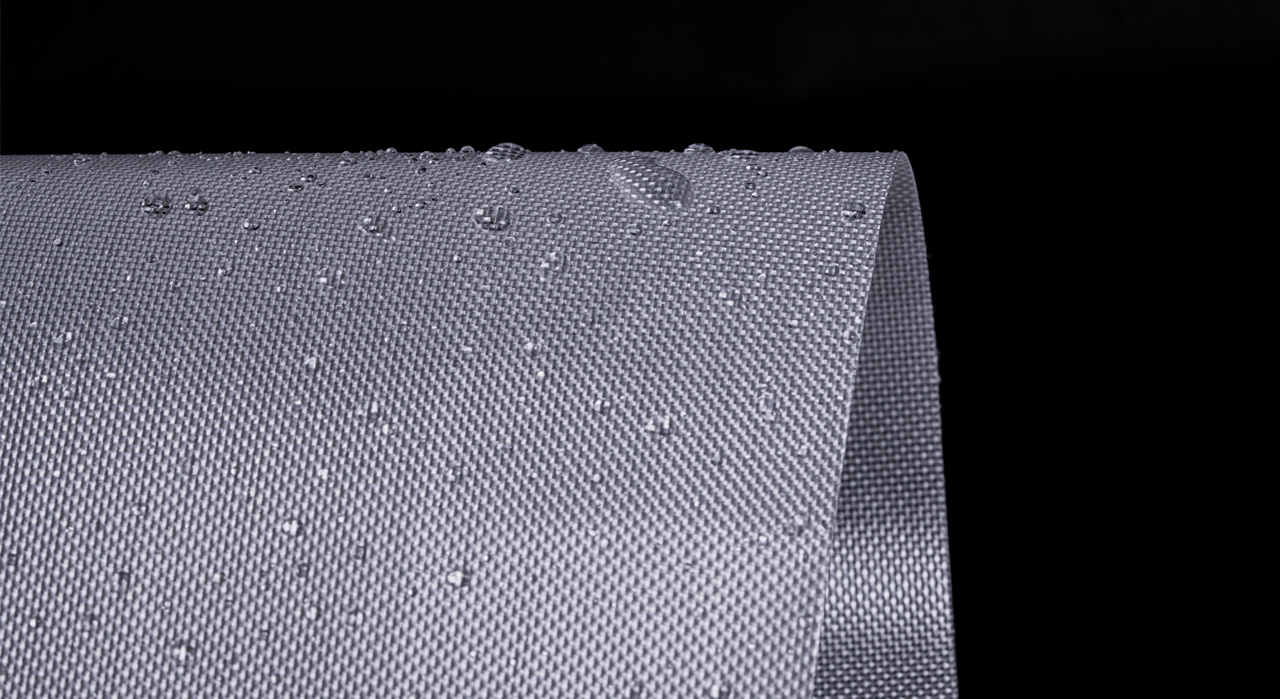

Durlyte™ – “The world’s most durable fabric.” Combines an ultra-tough film with ALUULA Core™ for extreme abrasion resistance and an 8x strength-to-weight ratio of steel. Available in 115 gsm to 220 gsm.

Graflyte™ – Strength meets softness. Waterproof, non-air-permeable, and ultralight, with the same steel-beating strength ratio. Weights range from 52 gsm to 125 gsm.

Sustainability Built In

Unlike most performance fabrics, ALUULA is designed with its end-of-life in mind. Being a polyethylene mono-polymer, it can be chemically recycled into ethylene gas, then repolymerized into new products.

The company is working with the University of British Columbia to scale these recycling processes—meaning even factory off-cuts can be reclaimed.

Their manufacturing process is also low-energy, low-waste, and low-emission. Future goals include introducing bio-based feedstocks and fully closing the loop for brand partners. It’s refreshing to see sustainability baked into the foundation rather than tacked on as an afterthought.

From Backpacking to the Moon

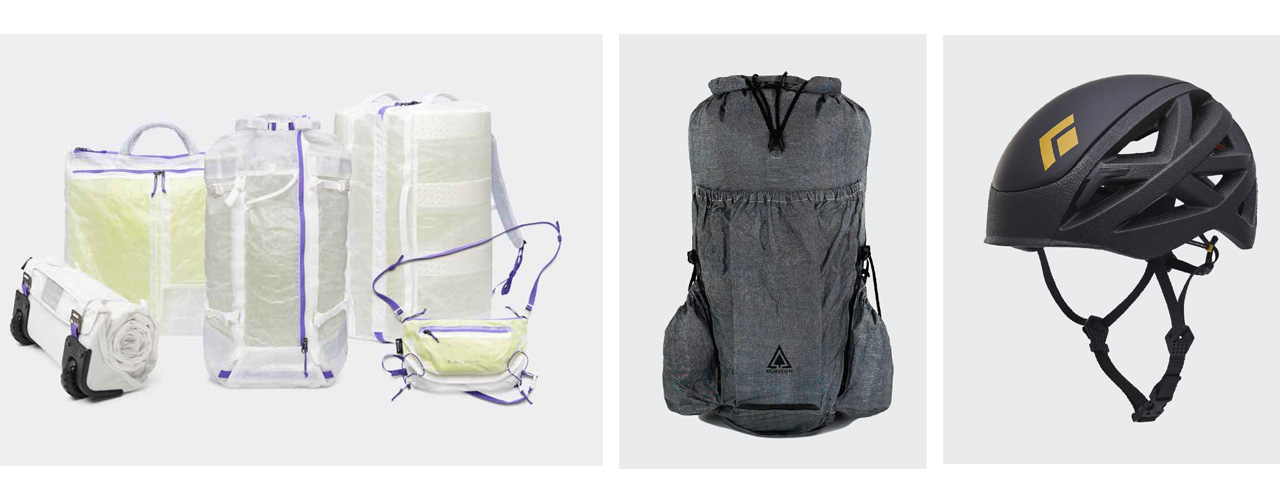

Today, ALUULA fabrics are showing up everywhere—from ultralight backpacks by Db Journey and Durston Gear to climbing helmets and alpine packs by Arc’teryx.

And they’re going further—literally. ALUULA is working with Michelin Inflatable Solutions on advanced inflatables, and with MaxSpace and NASA to build habitats for the moon.

If it can survive space, it can probably handle your next thru-hike.

The Future in Your Pack

For the everyday adventurer—or the seasoned carry enthusiast—ALUULA’s fabrics are more than a performance upgrade. They represent a new model for how gear gets made: high-performance without environmental compromise.

Lighter packs. Longer-lasting gear. A smaller footprint on the wild places we explore.

It’s not just an innovation in materials—it’s an innovation in thinking. And that’s something we can definitely get behind.

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews