Carry Materials III

For a larger version of the image, click here.

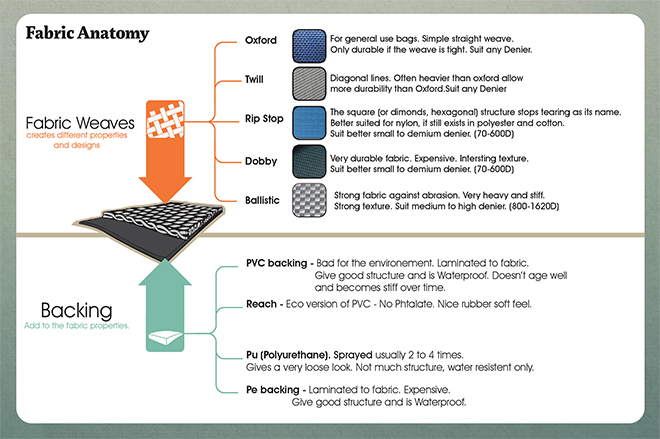

Our second Carry Materials post highlighted the properties associated with various materials utilised in carry products but now it’s time to provide some insight on why certain materials have certain properties.

Fibers are woven to become fabrics to which a backing is added, resulting in better resistance to tearing, abrasion, water, etc. These weaves come with different design textures and weight. Denier is a unit of measurement for the linear mass density of fibers. The higher the Denier the thicker the thread and therefore the heavier the fabric. The fabric weave provides part of the material’s properties and the backing provides the other part. The backing is either laminated or sprayed to the fabric. A good example are fake leathers, which are extruded polyurethane. They tear easily and don’t resist abrasion well but with the right backing they are much more durable.

The image above highlights different kinds of fabric weaves, as well as different types of backing that can be applied to the weaves to provide various properties.

Read more

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews