CORDURA :: The Business of Fabrics

When it comes to the world of carry, whether you’re a maker or a consumer, at some point you will have encountered the name CORDURA. The CORDURA brand is a major player in the fabrics industry, with carry brands around the world incorporating CORDURA fabrics into their creations based on their reputations for durability, abrasion resistance and strength. To find out more about this innovative brand Cindy McNaull, CORDURA’s Global Brand and Marketing Director, shared her insights about the brand’s history, products and innovative developments in the pipeline…

How did the CORDURA brand begin?

For over 45 years, the CORDURA brand has set the standard for what durable fabrics should be. The trademark itself was originally registered for a rayon-based product that was used in tires – “durable tire cord = CORD – DURA” (trademarked in 1929 by E.I. duPont deNemours and Company (DuPont)). In the mid 1960s, the brand name was transferred to DuPont’s innovative nylon formulations. About a decade later, as a result of a breakthrough in the process for uniform dyeing of nylon fabrics, colorful, rugged CORDURA brand fabrics – the forerunners of today’s technical fabrics -began to appear in soft-sided luggage, bags and technical packs developed by brands like Eastpak, JanSport, Kelty, and Manhattan Portage. Since 2004 the CORDURA brand has been the property of INVISTA, the world’s largest integrated producer of chemical intermediates, polymers and fibers. Known for their resistance to abrasions, tears and scuffs, today’s range of durable CORDURA fabrics are a primary ingredient in many of the world’s leading high performance gear and apparel products.

What have been the biggest challenges in the last 5 years?

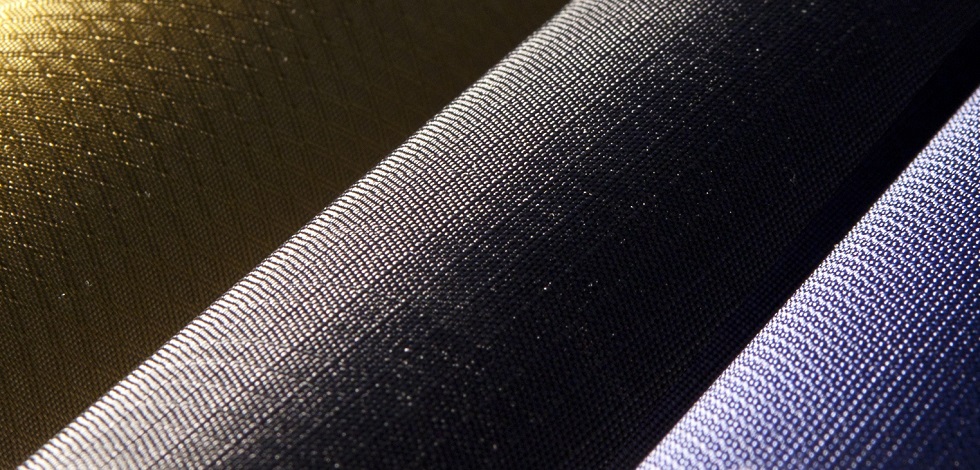

Although our CORDURA brand heritage has historically been equated with heavy-duty, industrial strength yarns/fibers used in rugged bag and pack cloths, our customers asked us to expand our offerings to performance and protective apparel. We introduced the ‘softer side of durability’ for apparel applications over the past 5 years, so this brought with it not only innovation needs but expanded branding opportunities for new classes of products. For example, comfortably durable CORDURA Canvas and CORDURA Denim fabrics which offer the wearer the authentic look and comfort of cotton, but with long-lasting performance due to added abrasion resistance. Other recent developments include our CORDURA Naturalle™ technical, lighter-weight fabrics for active outerwear. These offer durability plus functional features such as quick dry, moisture management or water resistance depending on the fabric finish.

What’s in store for the CORDURA brand in the future?

In keeping with our CORDURA brand tag line of ‘“Durable Fabrics for Durable People™”, we will continue to push the boundaries of head-to-toe durability with a wider platform of offerings for everyday lifestyle use. By not only living the lifestyle of our customers, but also integrating ourselves into the design community and working closely with our customers to identify unmet needs, we are continuously feeding ideas into our innovation pipeline. Recent developments such as CORDURA Air Flow Technology (AFT) for footwear, apparel, and bags, as well as CORDURA Lite Plus fabrics for lightweight super-strength bags and luggage have been the result of our drive to innovate and meet today’s durable design needs. Our technical team is currently working on new CORDURA brand technologies such as durable wool and even flame retardant fabrics for protective apparel.

Share with us a business ‘moment’ that you are most proud of?

The launch of our CORDURA Lite Plus fabric line was a milestone for the CORDURA brand. This was an example of our innovation pipeline at its best. From brand customer and consumer feedback we gained insight into the demands for lighter, stronger fabrics that did not sacrifice durability. By leveraging our technical expertise and heritage in automotive air bag technology we were able to develop lightweight, packable fabrics with high tear strength. The nylon 6,6 used in these fabrics is weight for weight stronger than steel. CORDURA Lite Plus fabrics feature high tenacity low denier per filament yarns with increased/inherent coverage factor – the result being fabrics with significant performance advantage in tear and tensile strength as well as a smoother and softer hand versus traditional packcloth fabrics.

How do you test your product?

There are really three traditional ways that CORDURA brand fabrics are put to the test. We have a range of in-house and external tests that we can apply as needed to ensure that fabrics carrying the CORDURA brand meet our brand standards. We utilize methods such as Taber or Martindale abrasion testing or machinery such as the Instron® Universal Testing machine which measures tensile and tear strength. We also rely on product testers such as Helen Thayer, our brand ambassador, who tests out products made with our fabrics in her global epic adventures.

And often our manufacturing customers such as Timbuk2, Eddie Bauer, The North Face, Levi’s and Herock (workwear) undertake their own performance testing which allows us to gain insights from hands-on testing of their product ranges. We find this type of feedback invaluable and it helps us to feed our innovation pipeline for the future.

Where are your materials sourced from?

Qualifying fibers are sourced from our global manufacturing sites and then sent to our global network of authorized mills who then produce fabrics that are sent to us for CORDURA fabric testing and brand qualification (each CORDURA fabric that is developed has to meet established brand standards). More in-depth details regarding our CORDURA fabric technologies and the authorized mill network where they can be sourced are available on our website.

Is CORDURA active in CSR?

Our brand team launched the CORDURA Cares(SM) sustainability program in 2009 as part of INVISTA’s commitment to environmental, health and safety excellence, as well as providing long-term value to society. The program consists of three pillars: Sustainable Performance, Enduring Materials, and Corporate Responsibility. These pillars are anchored by the tagline “Sustainability Begins With Products That Last.” We are constantly looking at increasing the utility and durability of our products and other ways we can benefit the environment. For us, durability is nothing new. It’s who we are and will continue to be.

What key insights drive your stuff?

Basically our developments are driven by unmet needs that we identify by both customer insights as well as market and fashion related trends. Consumer insight research also has a vital part to play. At the core of our innovation is the drive to constantly push the boundaries of durability and continue to expand our portfolio of “Durable Fabrics For Durable People™”.

What doesn’t the public know about the fabric game?

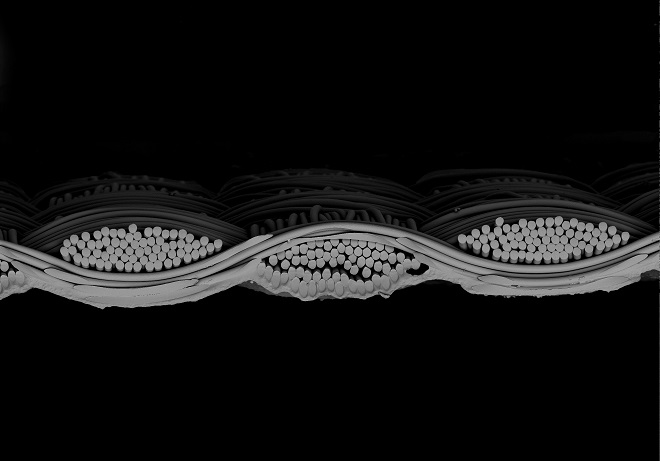

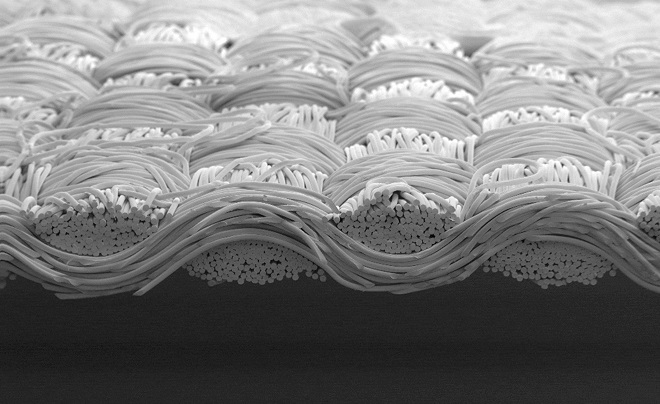

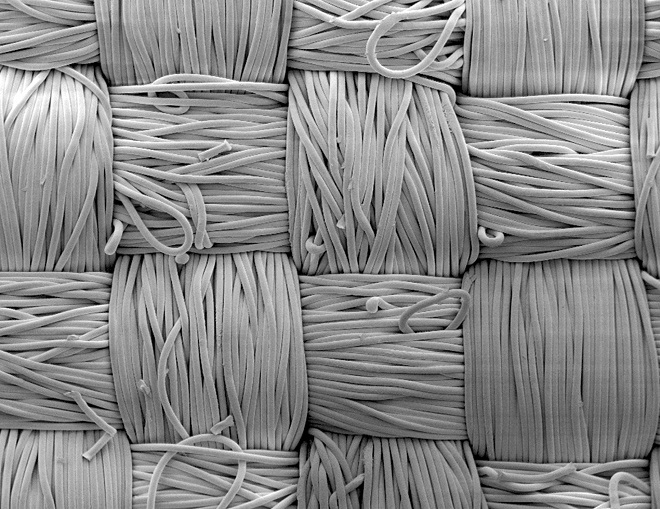

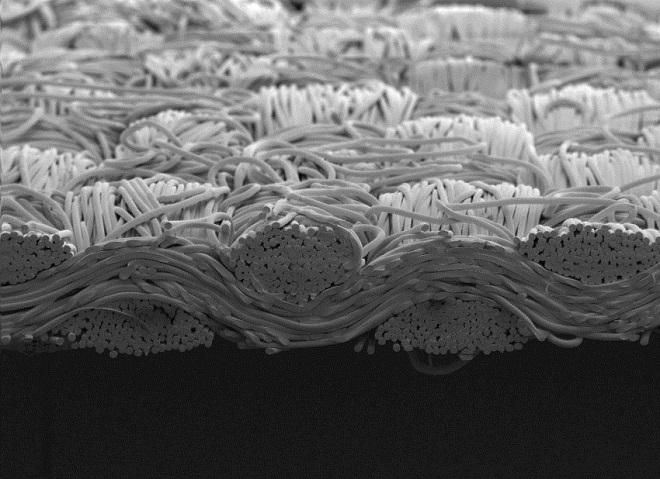

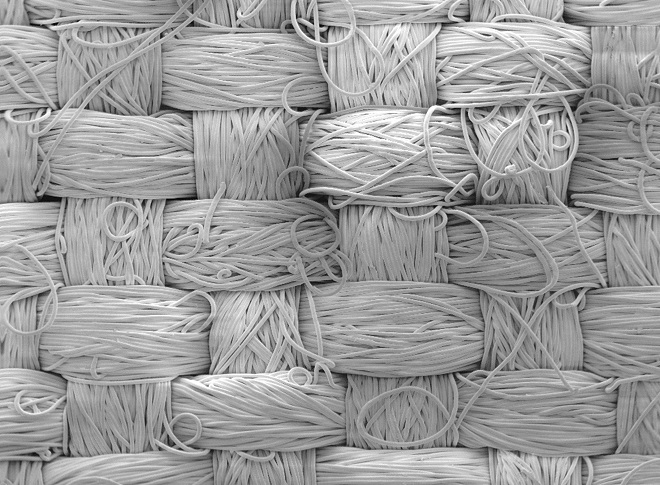

Textiles have been around for a long time, but many of today’s fabrics are a far cry from the basic cloth in use around a century ago – or even a decade ago. The basic process to make fabric is to take fiber, spin it into yarn and then weave or knit the yarn into fabric. The fabric can then be dyed to impart color and/or finished with chemistries to impart additional properties such as durable water repellency, etc. In today’s world of technical textiles, every decision made at each of these stages in the textile manufacturing process can have a huge impact on how a fabric will look, feel and perform. Should you use a natural fiber or a synthetic, what if you blend the two together? How thick or thin should the yarn be (i.e. denier), does it need high twist, is it wrapped core technology? What construction? Knitted or woven and if so, what knit or weave pattern – circular knit, rip-stop, dobby, ballistic or twill weave? What color or pattern? What dyeing technology works best for the fibers in the fabric? Does the fabric need to be waterproof? Is the best result achieved by applying a coating or by lamination to a membrane?

Behind the scenes, it can be an incredibly complex process to achieve something that on the face of it looks like “just another fabric”.

How has the fabric landscape changed in recent times?

Across all of the segments that we participate in, we’re seeing a growing requirement for fabrics to be much more technical in nature. At the same time, we are also seeing a growing movement for fashion to incorporate more performance-driven design concepts as well. To achieve these fit for purpose end-use requirements, not only are the products or garments designed to meet a specific function, but the fabric style, selection, and performance attributes must be considered as well. In particular, the increased need for lighter and stronger fabrics that do not sacrifice durability has been a game changer.

What makes your company/brand so special?

Our parent company, INVISTA, is one of the world’s largest integrated producers of chemical intermediates, polymers and fibers. With a business presence in over 20 countries, the company’s advantaged technologies for nylon, spandex and polyester are used to produce clothing, carpet, car parts and countless other everyday products. INVISTA’s global businesses deliver exceptional value for their customers through technology innovations, market insights and a powerful portfolio of global trademarks including COOLMAX, CORDURA, LYCRA, and STAINMASTER. More information on INVISTA can be found at www.INVISTA.com.

Specific to the CORDURA® brand, we are especially passionate about durability and work to continually innovate our brand. INVISTA’s CORDURA® brand team draws on a heritage of innovation and seeks to push the limits of durability to empower new generations of “Durable People” with an evolving pipeline of best-in-class durable fabric technologies.

What has been your biggest mistake business-wise?

Going back to your question regarding biggest challenge over the past 5 years, we wish we had introduced our apparel fabric innovations sooner since they’ve been so well received!

What did you learn from that mistake?

Quite simply this underscored our emphasis on listening to our customers, focusing on their unmet needs, and not being afraid to embrace new challenges.

Who else is doing rad things in the world of fabrics and why are they important?

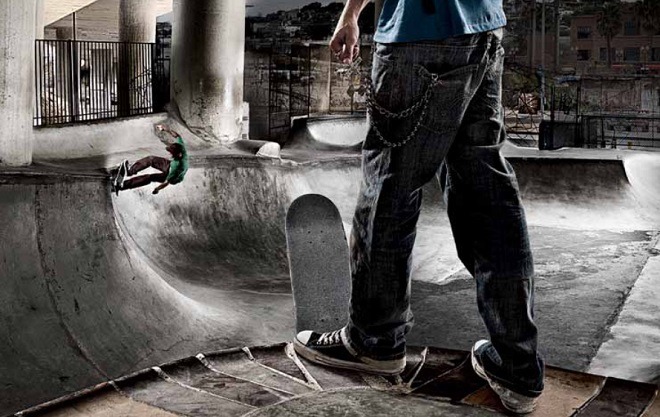

Our global authorized network of mills play a vital role in helping us develop new and cutting-edge CORDURA fabrics, and we love to see the different ideas that they present that extend the boundaries for the CORDURA brand portfolio. Then there’s the brands themselves. For example, the latest Levi Skateboarding Collection featuring CORDURA Denim and Canvas fabric as well as Eddie Bauer’s Sportshop line are awesome. We are also impressed by the new products we are seeing from our innovative Japanese brand customers such as Porter, ACE and master-piece. And of course, our loyal messenger bag customers such as Manhattan Portage (longest continuous running CORDURA® fabric customer since 1982) who continues to bring out New York Tough® inspired collections featuring CORDURA Classic and CORDURA Lite fabric, REI with their latest bags and packs with CORDURA Lite/Lite Plus fabrics, and Timbuk2 who recently launched their new and improved 25th Anniversary Classic Messenger bag featuring our latest CORDURA Lite Plus fabric.

Additionally, this year we announced our first Durable Design Achievement award. This award was presented to Jeff Knight and Dan Cruikshank, co-founders of Granite Gear, and recognizes their commitment to crafting high performance, innovative products. Their Quetico Canoe Portage Pack made with CORDURA Lite fabric is designed with true ergonomics and functionality in mind and was inspired by their company roots.

What do you think could be improved in the fabric industry?

Regional sourcing efficiency needs to be improved. We are finding that increasingly there is a drive from our customers to be able to make and source products locally, so there needs to be more collaboration within local and regional supply chains for full product production manufacturing integration. We are continuing to follow this development closely.

Tell us what your personal favorite fabric is and why?

I love our CORDURA Denim fabric because of its versatility and its fashion-forward edge. It’s got a classic look, it’s super durable and there are lots of added extras to make it both functional and exciting. Plus it crosses many different end-use boundaries. You’re just as likely to find it in messenger bags from Timbuk2 or durable workwear from CAT Apparel as you are to find it in jeans for skateboarding (Levi’s), cycling (Swrve) or award-winning climbing capri pants (Millet). And with the latest range featuring thermoregulation capabilities to enhance warmth or cooling properties when needed, who knows where we’ll see CORDURA Denim fabrics next.

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews