Insights | Horween Leather

Insights | Horween Leather

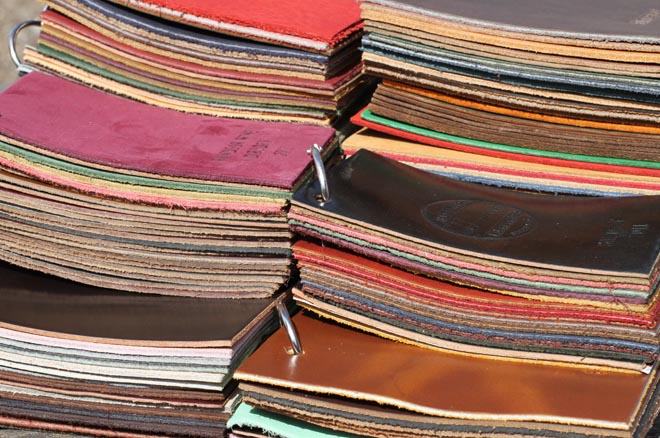

We thought it was about time we looked a little more deeply into leather, as the stuff makes up a huge chunk of the nicer carry products we use. And what better place to find answers than with Horween.

Based in the US since forever, Horween is one of the world’s great tanneries, producing hides for many of the carry brands we covet.

Leather is a foundation material for carry, and that makes sense. I mean skin evolved to carry around those big hunks of meat and bones we call animals, getting dragged through chaos and crud, and coming out relatively unscathed. It’s tough, it’s flexible, and if treated right, it lasts approximately a life time, so it’s perfect for carrying stuff.

Of course there’s more to Horween than their carry leathers (they make the leather for NFL and NBA game balls, for high-end footwear, and for all sorts of high-end apparel brands). Chances are you regularly at least look at their stuff, if not shove it in your pocket or on your back.

If you’re after a leather 101, we recommend Wikipedia. Today, we want to go a little deeper. So rather than us blabbing about it, let’s fire up some dialogue with the experts, as we dive into the sort of questions we’ve wanted to ask for ages. Here is a little Carryology x Nick Horween…

First up – what makes Horween Horween? Is there a core difference from other tanneries, or is it a mix of things?

We are keenly focused on making products that are of the highest quality. This means we use components of the highest quality, but it also means we’ve made a real investment in our work force. Whenever we develop something new, we always make it the best way we can, and then we figure out what we need to sell it for.

Lots of your leathers seem to have a real depth to their look, where there’s almost layers of interest. Is that magic, or is it just taking your time and doing things right?

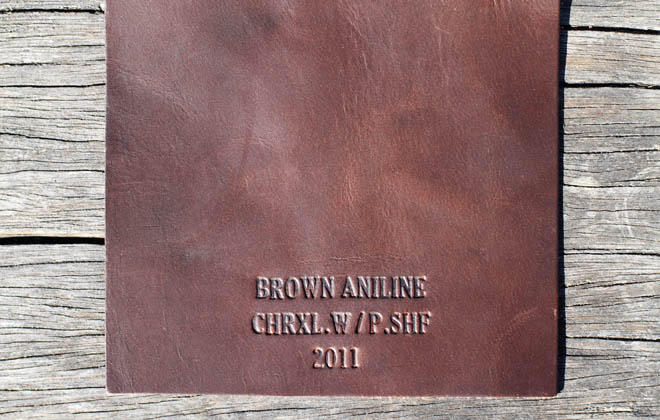

Both. We use primarily aniline finishes, which are like stains or varnishes for woods (as opposed to paint, or pigment). We achieve the depth of character by taking a traditionally tanned piece of leather and layering and building up the look we want.

How important is hide selection? Or does most of the craft happen within your walls?

It’s extremely important. When we receive the hides, we have no idea what the actual grain will look like. We actually won’t know until we’ve trimmed the hides, removed the hair, and preserved them. At this point we sort them and the hide really tells us what it can be made into. We sort for size, thickness, and grain quality. For grain quality, we’re looking at anything that effects the physical or structural appearance of the leather – brands, bug bites, healed scratches, etc. Hides that have these attributes aren’t “bad,” they’re just better suited for one leather over another. We buy the best hides available to us. Heavy, North American hides with as few brands as possible.

For a company with such a rich heritage of leathers, do you find much room to innovate and add new ones? Or has it all been done before?

We constantly have to develop and evolve. It’s true, we have a very strong group of core products that will always be made the same way. But, there’s constant pressure from overseas in the way of pricing. We’ve stayed the same because we believe that the customer can tell the difference.

Are there particular brands or designers that really push you guys?

Since we make everything to order and we’re willing to make reasonable changes to our products, there’s a real synergy between between customers and us. We’re lucky in that we get to work with really great companies and designers.

It must be very rewarding to see your leather used as a building block in all kinds of amazing products; are there ever finished products that you look at and think they could have made better use of your leather? Or, are you simply happy to have done a good job on your end of it?

There have been some products over the years that haven’t been the best examples of how our leather can be used. Of course, we want every shred of leather we make to turn into beautiful products that someone will have forever, but that’s not realistic. We are happy to have done the best providing one of the components in an end product.

Not many tanneries are expert in sporting leathers. Is there much difference between a shoe leather and a football/basketball/sporting leather?

Not in the philosophy of how we make them, but they are tanned and processed in very different ways.

Any thoughts or advice for really thick or really thin leathers?

You can always make thick leather thinner, but not the other way around. Thick leather is more expensive because not all hides are thick, and because it takes more time and materials (and muscle) to tan them. Thick leathers shouldn’t be split or skived too much, as this can compromise their strength.

Is there any way for consumers to tell how well a leather will wear in when looking at it in a showroom?

Other than knowing where it came from? If the leather feels overly springy or spongy, or the back (flesh) side of the leather is shaggy, those can be red flags. A really stout piece of leather should be able to handle repeated flexing and bending without breaking down.

Do you filter which brands and individuals you sell to, or do you sell to anyone that wants some Horween?

We sell to pretty much anyone that wants to use our products. The only exception to this is with our Shell Cordovan. We’re fortunate in that we’re able to sell every piece that we make, but limits in the supply of some of the raw materials keeps the numbers we’re able to produce relatively low.

Any new or returning leather trends that you’re feeling?

The market seems to be understanding that leather is a natural product, and it’s always going to be a little bit different. This is great because leather that is allowed to look and feel like leather often performs and ages the best.

Any great leather resources you can recommend for readers looking to increase their knowledge?

I try to put some information up on our blog, and if readers are looking for specific answers I’m always willing to take suggestions. There’s some pretty good info on the SATRA website, but I think much of it is members only.

What’s next? What gets you guys out of bed in the morning?

Every day is different. The one thing that every tanner will tell you is that you never know it all. There are so many different ways to do things, and so many different steps and tanning materials, that the possibilities are endless.

There was mention awhile back of your own branded products. Is that still in the mix?

We’ve been doing limited runs of products under Genuine Horween Products. So far it’s been belts and some accessories – all in small quantities of high quality items. The idea has been to take something we do well, and work with a crafter to put together something that’s special, without competing with our customers. We’ve got some great samples that are almost ready.

How long does it take to make a piece of leather?

It varies on the tannage, but the range is 1 – 6 months.

—–

Extra reading

Still want more? Here’s a few other choice bits about Horween:

http://horween.wordpress.com/

http://gearpatrol.com/blog/2010/03/25/horween-leather-interview-with-nick-horween/

http://www.styleforum.net/t/274603/nick-v-interviews-nick-horween-horween-leather

Images are either from Horween Leather or shot by Carryology. Thanks to Horween for being so rad about our questions.

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews