Wilboro Leather Molding and the Victory Case

Following on from our ‘Insights :: Wilboro’ post which provided a taster of one of Will Ficner’s favorite carry projects, we bring you the post below, again courtesy of Will. He explains a carry design technique which you can try yourself (and if you do, we’d love to see the results…)

–

A number of years ago when I had only started to dabble in leather working, adding the leather as an element into some fabric bags, I came across a bag that had these two neat leather molded back pads on it. I thought “hey I could do that” so I did a bit of reading on the subject, made a simple positive and negative wood mold, got some leather, clamped it in between the two pieces of the mold and hoped for the best. The results looked okay, but unfortunately the leather I used was chrome-tanned not vegetable-tanned (sold the wrong leather at a local store) which is what you should be using.

Throughout the years I continued to work with leather and I found it fascinating to look at old product designs. While researching some older fastener systems I stumbled across these superb leather map cases from WW1 and WW2. It seemed that a number of countries made them in different variations, the Swiss, Germans, Polish and possibly others. The closure systems are what made me look at these cases originally (which I often use a variation of on the Victory case) but the insides of the cases had these molded leather bits for pencils, rulers and compasses which were amazing-looking.

I thought to myself “I sure would like something like this but updated for the modern things I normally carry”. That’s where the idea for the Victory case was born and my serious attempts to master leather molding began.

Here are some of the details around how I have been doing the molding. If you’re game try it out yourself!

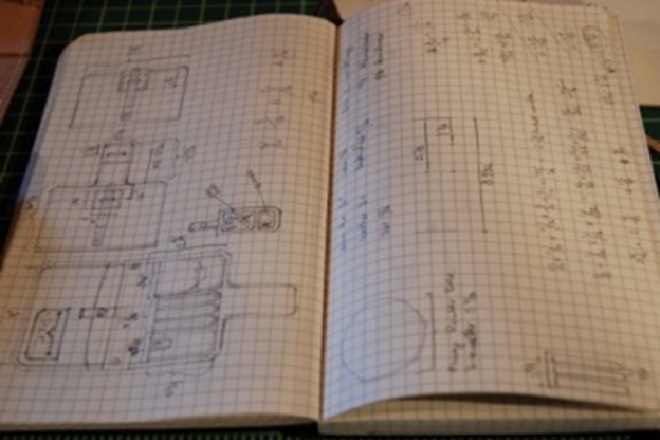

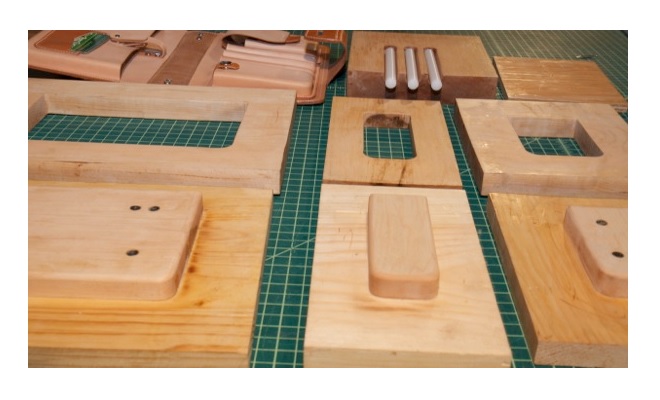

The first shape I attempted was to mold a single cigar-shaped pen holder and I wanted it to fit a large diameter pen up to about a 0.5”. I first made a single pen mold, then a double and finally a triple as the previous ones worked.

This is how I did it: I started by using a round nose router bit and routing a slot into a piece of pine, which would become a positive mold. Then I made the positive side of the mold by turning a wooden dowel to roughly the same shape but smaller than the negative mold. It has to be smaller to accommodate the thickness of leather used. In my case I use roughly 5oz or 5/64” thick leather and leave a space of roughly 5/64 – 1/8” around all sides of the positive mold to accommodate the thickness of the leather.

The next step is to cut a piece of leather (I used Wickett and Craig tooling/holster/carving vegetable-tanned leather in a natural finish, but have since found most vegetable-tanned leathers will work) and dunk the piece of leather in cold water until it’s soaked through. I then place the leather topside facing the negative mold (you want the smooth top-grain on the outside), press the positive mold into the back of the leather, then take a piece of flat wood on the backside and clamp it all tightly together.

I let everything stay in the mold for about 24 hours, trim excess leather off the end, then take the backing wood off to let it dry out fully for another 24 hours. This works amazingly well; when I first attempted it I was not at all certain I could push the leather this far without it splitting.

One major modification was made in the mold material as I experimented. I switched from soft pine to hard maple for the negative mold (the pine warped and split during a few early attempts). It’s important to use a wood that doesn’t have a very defined grain, like oak, since the leather will actually take the grain imprint. I then coated the wood with paraffin wax and torched it in for waterproofness; it also allows the leather to release more easily.

For the positive part of the pen mold I started using Delrin plastic for waterproofness and anti-stick properties. You could use Delrin for all parts of the mold but it would be pricey.

Once the leather has dried you can remove it from the mold and trim the excess off.

The rest of the molded pieces use a positive and negative mold as well. The only difference is since they have flat tops, the negative part of the mold can have an open top. This eases in its construction and allows the moisture to escape faster from the form and dry more quickly.

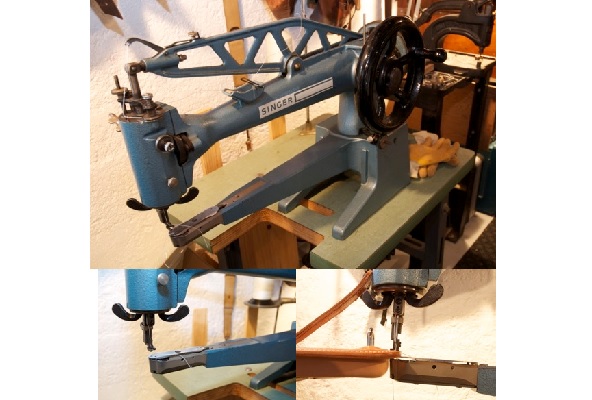

The other challenge with the production of the case was stitching the molded inner sections to the outer jacket of the case. Because part of the closure system had to be attached to the outside layer of the case before the insides were sewn in, the case wouldn’t sit flat and you couldn’t use a flatbed sewing machine to sew around the edges. I wasn’t keen on all the hand stitching and my cylinder bed machine just couldn’t get close enough to the edge without the molded pieces interfering. So I actually ended up buying a used/old Singer patcher sewing machine which can get in much closer. It’s also great for getting deep into bags to do tricky seams and you can rotate the head to sew 360 degrees which is amazing!

Here are some pictures of the final product. It features the following:

This type of closure (a very old system) is being used a lot more in the last few years; the great thing about it is it’s simple, easy to use, and very durable.

I find this case excellent to use if your bag doesn’t have a lot of organizers. It’s also fantastic for traveling as it provides easy access to all my necessities, especially when seated on a plane.

All in all I really like the results of leather molding and have started using it in a lot more projects. It’s time-consuming making the molds but the outcome is worth it.

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews