Victorinox :: The Science of Luggage Testing

Each piece of luggage weaves a tale, sometimes a good one and sometimes a bad one. Perhaps when looking at your scuffed-up but still-going-strong piece of luggage you are reminded of the amazing journeys you’ve had with it. Each scratch and mark serves as a little postcard of where you’ve been and you can’t wait to add to your collection of memories. Other times, you may remember a piece of luggage with a grimace of disdain – that snapped handle as you were racing to catch the train, the popped lock or hinge that led to your contents making a bid for freedom across the airport floor, the wonky wheel that decided it was going to have a solo adventure regardless of where the rest of the case was going.

At some point you might have wondered what kinds of product tests your luggage went through to ensure it held up well (or alternatively what kind of tests it should have gone through to avoid the pitiful piece sulking in your cupboard). Well to shed some light on the situation Tim Lynchard, the Victorinox VP of Distribution, shared his insights on the brand’s luggage testing processes…

What’s your philosophy when it comes to testing?

There are two aspects we need to touch on in terms of product testing. First, the product needs to comply with the regulator’s requirements or voluntary standards/requirements. Second, the product needs to meet certain performance tests such as abrasion tests for the shell fabric and mileage tests for the caster wheels.

At this time there are no clear regulatory requirements for travel gear products. Aside from voluntary tests, we also conduct product performance tests to make sure the product is up to standard for the purposes to which it has been designed. Most of the test results are then used to set ongoing performance specifications.

What are the major challenges?

With a brand like Victorinox, consumers have high expectations. As new features are built into new products, it is always a challenge to design suitable test methods quickly enough to meet the demand of the new feature(s). It is also a challenge for us to set adequate performance requirements for the products within a limited product development cycle.

What standards must every piece pass?

As a premium brand, each piece of product is required to meet all of the voluntary standards and set performance tests.

Do standards vary with different levels of product?

Yes, there are different tests for different product ranges. For example, an upright with wheels requires mileage testing while a backpack will require a shoulder strap jerking test. There are some overlapping quality tests such as colorfastness to light and abrasion tests for fabric. If the same fabric is used on these two product types, then the test requirements will be the same.

What kinds of tests do you run? Explain the tech used in each?

There is chemical testing as well as physical and mechanical testing involved. To comply with REACH in European requirements and Proposition 65 requirements in the U.S., chemical tests are also required.

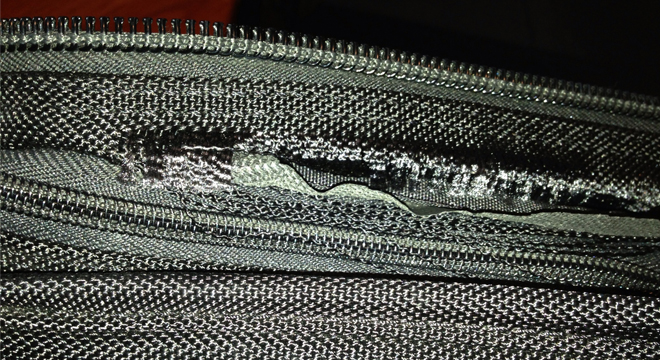

In terms of performance testing, there are fabric abrasion tests, seam strength tests, zipper performance tests, product drop tests and jerking tests on carry handles. We run a number of different tests for each product category.

For instance, with the drop test, we load a piece of luggage with weight and then drop the bag from a designated height. This is repeated for a significant number of cycles to ensure it meets our testing standards.

How often do you have to invent new tests for new product?

Typically a new test method is created and/or an existing test method is modified annually. The development of a new test method is dependent on the design of the product and the relevance of the existing test method to the product. If there is need, we will design new testing for the specific product design.

Feedback is king, do you compare the returns you get to your test results/simulations to make sure you’re testing the right things?

We do value the feedback from the field and consumers after they use the product. We have a channel to collect this feedback from the market. Once we receive the feedback, we review any issues to evaluate if they are the result of product abuse or a manufacturing/design issue. After we evaluate the feedback and the product, we make the appropriate adjustments as well as fine-tune the manufacturing process and update or design new testing methods.

How has your testing changed in the last 5 to 10 years? What factors have impacted it?

The voluntary regulatory requirements continue to change and become tougher as environmental protection awareness increases. Consumer expectations reinforce this as well.

We designed new tests based on the feedback from the field and new design. For example, we developed a sway test for briefcases because a specific market is very much concerned over how quickly the D-ring connected to the shoulder strap may wear out and fail. We also designed a caster wheel noise level test to ensure the sound generated is not too loud during use.

Do you ever test competitors’ products?

Yes, we typically test our competitors’ products under a few different circumstances: We will test if they come out with a product that has a new or improved feature and to test different types and levels of their product to see how it performs compared to our own and others in the industry.

What are the main ways competitors fail?

This is extremely variable and depends on product type and performance specification we are testing against.

What can you learn about how bags fail?

The test failures help us to make improvements to the manufacturing and/or product construction process. Also it helps us in future product design.

What does it take to be an awesome tester?

Step 1 is ensuring that we consistently test our product well and communicate results.

Step 2 is ensuring that we are continuously asking ourselves how we can improve current test methods, as well as design methods that meet the needs of how our product evolves.

It also helps to have safety goggles, ball bearings and a protractor.

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews