Core77 Ultralight series :: Part 3

Core77 keeps the awesomeness rolling with their lightweight and ultralight backpacking series. Following on from their interview with Mike St. Pierre of Hyperlite Mountain Gear Core77 chatted to the founder of one of the most well-known brands in backpacks, Osprey. Posted below in all its carry goodness is Unpacking “Ultralight” with Mike Pfotenhauer of Osprey Packs by Kat Bauman…

–

Whether you think ultralight backpacking sounds like hell or vacation, it provides a special dilemma for design minds. Ultralight gear has to be minimal, ergonomic, versatile and very, very light. To get a higher-level industry take on the lightweight challenge I spoke with Mike Pfotenhauer, founder, owner and chief designer of Osprey Packs. Osprey is over four decades old and renowned for innovative, ergonomic and, yes, lightweight pack design. Still independently owned and operated, they’re a leading name in multiple fields of backpacking. When I caught up with Mike he had just gotten back from Southern California – a region he’s required as a Northerner to speak poorly of – where he’d had a nice time hiking around Big Sur. (Don’t tell him I told you.)

You guys have been doing pack design for a very long time. What sparks new ideas now?

For us a new design is often a compilation of older ideas that finally make sense. We build many iterations when developing a new product. Often it requires a minimum of 15 or 20 different versions before we can finalize a new product. All of this experimentation is never wasted. Our prototype archives are loaded with innovative concepts that are just waiting for the right opportunity. We have a lot of ideas stored. In fact, I just told everybody we have to dig out today! We have so many prototypes we’re tripping over them! It’s insane, we’re drowning, we could get lost in them!

Do you still have a hand in the design process?

I’m definitely still involved in the design process. We have a design office in Mill Valley, and up until two years ago I did almost all of it. Now I have two design assistants and a production manager, and the design team in Vietnam, who turn the designs into prototypes and so on. We get a lot of input from distributors and vendors too. We travel to Vietnam where we have 35 people in the development office. With web conferencing we keep the product on a 24-hour development path. They build samples and ship them here or we go over them online, and go over them again and again and again…until the curtain. It’s been worked to death by then. So that’s three designers – two less than half my age, which is interesting. Young minds to keep me thinking young.

You guys just put out a new Exos. What’s your take on going ultralight from a design perspective?

I really appreciate limitations. With any lightweight gear you have that rule – you want to keep it simple. It’s also nice from a sustainability angle. Less process, less material. I do gravitate towards lightweight, towards minimalism. I like the challenge to strip things away. We’re pretty known for that – gear that’s lighter but durable. Not too light, though. We have an extensive warranty program and we don’t want stuff coming back. Or getting thrown away!

How do you determine desired weight and work towards it?

Comfort, efficiency and load transfer are the concerns at the top of our list. Once we’ve accomplished those we do what we can to strip weight where it won’t be detrimental. Because we develop our prototypes entirely in-house we know the product intimately and every gram that’s not pulling its weight is discarded. With the Exos we knew that a highly tensioned back panel would be far lighter and more comfortable and ventilated than one with plastic or foam. We stripped dense foams out of the hipbelt and shoulder straps and created more ventilation by using layers of 3D mesh.

How do developments in high-tech materials affect your line?

We have developed very close relationships with our raw materials suppliers over the course of 40 years. In concert with our own large development staff in Vietnam, our country of origin, we are continuously refining our materials and pushing our suppliers for new innovations. They know that we often cannot make the leap to the next performance level unless they work closely with us, perhaps a new fabric coating or 3D mesh with unique properties.

When you’re considering the ergonomics of a new design do you build on previous assumptions about what works, or go back to drawing board?

Our ergonomic design follows the principles we see in human anatomy whenever possible. We see parallels in our materials. Fabric is skin, framework is bone, webbing is tendon, and so forth. In the Exos, we created a breathable skin tensioned over framework as the interface with the body. The framework supports the load which in turn is transferred without pressure points to the wearer’s back via a tensioned skin of airy mesh.

I consider pack design an art. It’s like a 3D kinetic sculpture, and since it’s being worn by the body it has to work with the body, so ergonomics are critical. I studied art and do a lot of life drawing, and it’s a great model for the design. It should be comfortable – it’s the best way to get someone interested in the product! That it doesn’t cause pain. It’s a great design problem. It’s as complex as the human body, so it’ll never be fully solved.

It’s all from me doing this for 40 years. Sometimes my wife accuses me of sleeping with our packs! I’ve got 6 packs on the floor of our living room. Do a lot of work from home, or wherever I am. Art is my go-to thing – I carry a sketchpad everywhere. I’m most interested in the connection to the body, the hipbelt and suspension. How the load is carried by the body. I pay less attention to the front of the bag. There are other people who do that better than I do.

Roughly how long before a new idea is prototypable?

We often generate prototypes same day that we think of it. Write up a list of design comments, I have an assistant in Vietnam, and we’ve spent ten years working together so he knows how I think and he’ll fill in the gaps. He’ll get together a prototype basically overnight. Something concrete to look at and bounce ideas off. The sooner you have something concrete to work off of, the better. Even if it’s really bad! That synergy you get working with someone else who doesn’t quite get what you’re thinking is informative too.

We time the trips to Vietnam to be close to actual production. We learn a lot from the producers about necessities in production, what might not work. It’s a constant collaborative thing, none of us get too emotionally tied up in the product. I guess since I own the company I don’t set up gates and deadlines. I’m willing to work up until 11:59 to get it done.

At what point does aesthetics enter the design process?

The work in progress can start out looking funky and cluttered. We push aesthetics and performance equally along the development path. We keep our sample goggles on knowing that in the end pattern tweaking, final fabrics, colors and blocking will help pull the required look together. Some concepts are doomed because they are just too scary and alien. That’s the stuff we archive for later when we’ve figured out how to tame it.

How would you describe Osprey’s brand philosophy?

I’m terrible at this. I keep getting asked to come up with a Mission Statement, or a Vision. We do what we’ve been doing, and we’re going to keep doing it! Maybe: Be involved in the making of the product. Most of our competitors will come up with great ideas but don’t have the ability to build prototypes and go to the factory to get them made, and they haven’t been involved in the making. I’ve been involved personally – in Colorado for 12 years. I know what they can and can’t do. We fully own the process. The manufacturers appreciate that we don’t just let them do it. They don’t want to have to do the creative work for everyone. I think that’s part of why so many bags look alike, companies are all pulling from the manufacturers’ same creative pool.

So I guess the philosophy would be to own what you do, be responsible, be as involved as possible. I miss the manufacturing! Not the hard work, but the excitement of seeing the product made. We’re debating having our own proprietary processes, to be able to produce our own parts and things like that. I like to stay involved, I’d hate to give that up! I enjoy being away from the sales and marketing.

What do you think makes Osprey distinctive?

What makes us the best is our long history of doing what we’ve been doing. Never broken by changing hands, change in philosophy. We hear from our athletes in the field, retail forums and reviews, and international distributors weighing in on how things are used around the world. There’s huge Chinese demand for skateboard packs – and not just skateboarding but longboarding! That market alone is bigger than our country.

Do you personally test gear?

I don’t take many extended trips. During the development of the Exos, I climbed a peak in the Sierras and backpacked around. There are tons of trails around Mill Valley, I use those to test. There are running and biking and hiking trails. I can just walk out my door and have endless trails to test stuff on. We do travel gear too, and I do a fair bit of travel particularly to Asia, so that’s easy.

Did hyping “The Guarantee” change your design thinking?

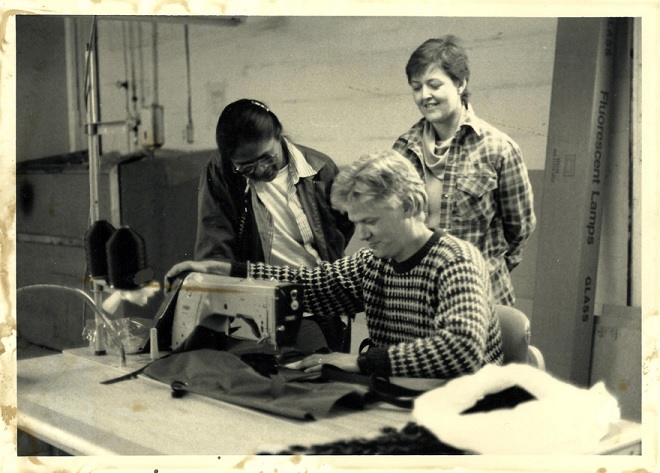

We always kinda had that, we just finally put it in writing. I guess the marketing people got ahold of it and went to town. We are trying to tie our warranty people better into the process, I think they sometimes feel left out of the design. So we’re trying to get that feedback better looped into the process. It’s only a team of about six people, with two or three doing sewing. We have a pretty good record on repair. It didn’t radically jump up our returns.

Working on anything exciting right now?

Yeah, for Spring ’15 I’m working on a new suspension system. The Exos was derivative of the Atmos – kind of a 3D trampoline back panel. I’m working to incorporate that trampoline into the hipbelt, and carry maybe 95% of the load there. Lighten it up further, ventilate further. I want to make the pack act more as a garment than something that sits hard with a lot of contact. I think it’s working! The prototypes feel a lot different. It’s always scary when you go into production – you never really know if your idea can be produced thousands of times. That’s the battle in Vietnam.

What other technical gear companies do you admire?

Black Diamond, Nemo, Big Agnes, Outdoor Research and Petzl.

What was the intention or inspiration that started your line of packs?

Since I was a boy, I have loved to build the gear that I use for any of my outdoor adventures. The design is only amped up by the building. Hands on in the processes of construction always takes you places your tweaky mind can’t fathom. Actually using it usually sends you back to the drawing board or sewing machine. I love that cycle. It’s the perfect combination of frustration and reward.

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews