Geeking :: Sailcloth bags

Geeking :: Sailcloth bags

OK, straight up, we’re actually talking about Ultra-high-molecular-weight polyethylene, but that didn’t fit in the header space. What is UHMWPE? It’s a space age material from the space age (you know, the 70s, when they had space travel and Concordes and all the fancy stuff).

UHMWPE more typically moonlights under names like Dyneema, Spectra, GUR, Cuben Fiber and all sorts of proprietary names. It gets woven, laminated, diluted, extruded and messed with for a range of products; from ballistic protection, sails and bags, to snowboard bases, surgical implants and chemical-resistant containers.

It’s super strong, super light, puncture and tear-resistant, abrasion-resistant, chemical-resistant and slippery like Teflon. So why isn’t it everywhere? Those long molecular chains are pretty expensive to manufacture, so the stuff ain’t cheap. But when it comes to carry, it works a treat for high-end ultralight gear, which is what we mostly wanted to talk about.

Why carry UHMWPE?

You can build a fully waterproof, tear-resistant, abrasion-resistant rucksack that weighs about what your plastic shopping bag does. If you’re going on an adventure where weight is a factor, you can treat it like crap and it won’t let you down (or weigh you down).

Why wouldn’t you carry UHMWPE?

Well, apart from the cost, it can be pretty stiff and crinkly, pretty hard to cut and put together (reducing the number of bag makers able to work with it), and you can’t get it in heritage herringbone.

So why are we starting to see it more?

Because weight matters. But also, mills are starting to weave and laminate it with other fabrics which makes the stuff more approachable to consumers, reducing the plastic look to it and opening it up to more mainstream applications.

Rather than keep talking in generalities, we thought it would be good to get John Canfield’s thoughts on the stuff. He’s one of our contributors, as well as being a bag maker (check out High Above) who has been working with the stuff a fair bit lately. Here’s what he has to say…

A few things right out of the gates…

Sewing it: The stuff is expensive. What I use is over 5 times the cost of 1000D Cordura. This is a key reason why it is uncommon for large-scale production.

Stitching it: The stuff is difficult to cut with scissors unless they are really sharp. The material resists being marked with pen or pencil, but thankfully takes permanent marker for patterning. It has zero stretch. None. So everything you do has to be spot-on, and when using the bags you can’t just keep cramming, as the stuff won’t give.

Specifying it: The larger of the small companies like CiloGear have special versions of it made for them. Some applications like shoes will not utilize this material in a pure form, but may use hybrid woven versions. I like versions of it woven on the bias, as it lends a slightly more tech look, increases tear resistance and strength, and adds a 90s vintage look.

Specifying it: The larger of the small companies like CiloGear have special versions of it made for them. Some applications like shoes will not utilize this material in a pure form, but may use hybrid woven versions. I like versions of it woven on the bias, as it lends a slightly more tech look, increases tear resistance and strength, and adds a 90s vintage look.

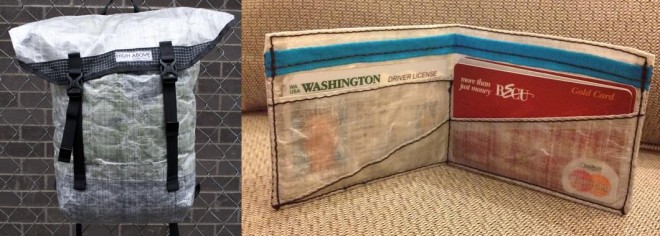

Which variants? Dimension Polyant’s VX line of fabrics are neat. I used VX51 for backpack panels while sewing at Mystery Ranch. VX21 is VERY common with backpackers. DP also make a hybrid fabric which utilizes Dyneema for higher overall strength. I also use Cuben a bit, from my 7.51-gram ultralight wallet to a back-to-basics hike/backpack I made from 2.4-Oz Cuben. The whole pack weighs well under a pound, which is approximately not much at all.

So that’s UHMWPE. It ain’t Tyvek, it’s expensive, and it’s a little hard to work with, but it’s pretty flippin’ incredible. Go check it out next time you’re in a super-exposed and remote part of the planet, trying to survive on only the basics as you brave the elements. You’ll probably find there’s nothing better.

So that’s UHMWPE. It ain’t Tyvek, it’s expensive, and it’s a little hard to work with, but it’s pretty flippin’ incredible. Go check it out next time you’re in a super-exposed and remote part of the planet, trying to survive on only the basics as you brave the elements. You’ll probably find there’s nothing better.

Further reading

If you’re keen to explore more UHMWPE, there are a few places to play…

Dyneema and Dimension-Polyant both have sites about particular versions of the fabric, and Wikipedia is helpful as always.

For some lists of products available, check the ultralight forums and blogs. TenPoundBackpack is great, as is BackpackingLight.

Or click any of the packs shown above for makers and their info. Happy hunting!

Carry Awards

Carry Awards Insights

Insights Liking

Liking Projects

Projects Interviews

Interviews